Kia Sportage: Spot welding

1. Commercial spot welding machines do not perform as well as the machines used in the manufacturing process. When spot welding, increase the number of spot welds by 30% (1.3 times the original number of welds).

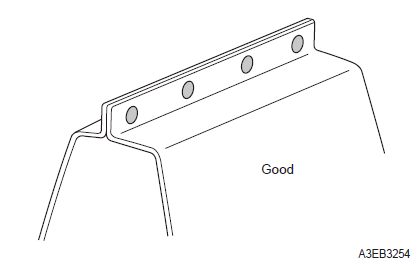

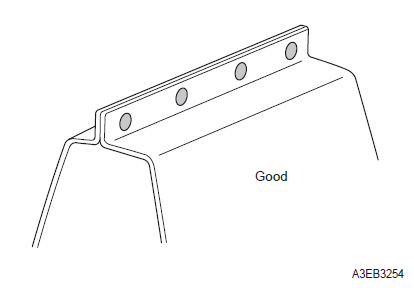

2. When spot welding, weld in the middle of the joint.

- Spot welding on the edge of the joint will reduce welding strength.

Carbon arc welding

In areas where spot welding is not suitable, do plug welding using a carbon arc welding machine.

1. Clamp the parts to be welded together tightly. Do not exceed 1 mm of space between parts. A tolerance greater than 1 mm will reduce the strength of the welded area.

2. Weld in the middle of the flange joint.

- Drill a hole 5~6 mm on one side of the flange only, and weld within the hole.

- Do not weld on the edge of the flange joint.

READ NEXT:

Disassembly - Replacing body panel

Disassembly - Replacing body panel

Disassembly

1. Body measurement

Before disassembling, measure the damaged area

according to the dimensions supplied in Body

Dimension, Section 31. If deformation is present,

use a frame str

Preparation for assembly - Replacing body panel

Preparation for assembly - Replacing body panel

Preparation for assembly

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark. Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any

Assembly - Replacing body panel

Assembly - Replacing body panel

Assembly

1. Checking welding and fitting in advance

When assembling a new part, measure the

dimensions of each part according to the body

dimensions given in Section 31, and set part to the

SEE MORE:

Brake Line

Brake Line

Components and Components Location

Components

Repair procedures

Removal

1. Disconnect the brake fluid level switch connector, and remove the

reservoir cap.

2. Remove the brake fluid from the master cylinder reservoir with a syringe.

CAUTION

Do not spill brake fluid on the vehicle,

Rear Cross-Traffic Collision-Avoidance Assist malfunction

and limitations

Rear Cross-Traffic Collision-Avoidance Assist malfunction

and limitations

Rear Cross-Traffic Collision- Avoidance Assist malfunction

A: Check Rear Cross-Traffic Safety

system

When Rear Cross-Traffic Collision-

Avoidance Assist is not working properly,

the warning message will appear

and the master warning light ( ) will

appear on the cluster. Have the function

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles