Kia Sportage: Disassembly - Replacing body panel

Disassembly

1. Body measurement

- Before disassembling, measure the damaged area according to the dimensions supplied in Body Dimension, Section 31. If deformation is present, use a frame straightener to adjust.

- When disassembling a panel, apply clamps to prevent damage of each part, and support the lower end of the frame to prevent deformation during the procedure.

2. Cut and welding point selection

Cutting, if necessary, should not be done in a reinforcement area. Select an area which will result in the least amount of deformation after welding.

3. Cutting rough area for replacement part

Cutting should be done according to the following steps to make disassembly easy:

- Use care when cutting an area close to a pipe or wiring harness.

- Cut an area leaving 30~50 mm of tolerance.

4. Removing paint from an area to be spot welded

Using a torch and wire brush, remove paint completely before beginning welding.

5. Determine a cutting method

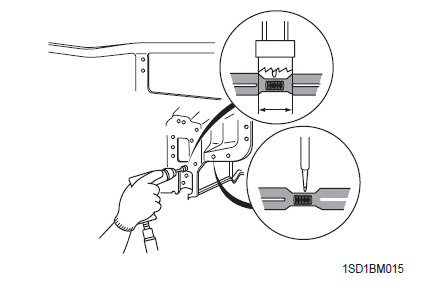

- Cutting a spot welded area

Make a hole in the middle of spot welded area with a punch, disassemble welded area using a spot cutter and remove using a chisel.

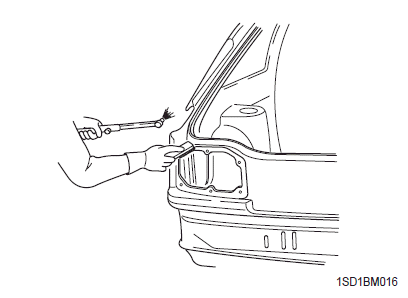

- Removing brazed area

Disassemble using a torch and wire brush, and remove with a chisel.

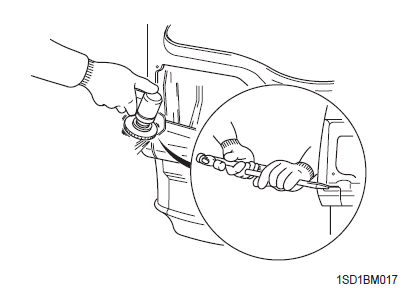

- Removing arc welded area

Remove plug welded area using a disk grinder and disassemble with a chisel.

READ NEXT:

Preparation for assembly - Replacing body panel

Preparation for assembly - Replacing body panel

Preparation for assembly

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark. Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any

Assembly - Replacing body panel

Assembly - Replacing body panel

Assembly

1. Checking welding and fitting in advance

When assembling a new part, measure the

dimensions of each part according to the body

dimensions given in Section 31, and set part to the

Fender apron panel assembly

Fender apron panel assembly

Welding part

Setion

Cowl panel assembly

Welding part

Section

Dash panel assembly

Welding part

Section

Center floor panel assembly

Welding part

Section

Re

SEE MORE:

Occupant Detection System (ODS)

Occupant Detection System (ODS)

Your vehicle is equipped with an Occupant

Detection System (ODS) in the front

passenger's seat.

The ODS is

designed to detect the presence

of a properly-seated front passenger

and determine if the passenger's

front air bag should be enabled (may

inflate) or not. Only the front pass

Seat belts - Front passenger and rear seat 3-point system with combination locking retractor

Seat belts - Front passenger and rear seat 3-point system with combination locking retractor

The following explains how to fasten the

passenger's and rear seat belts.

Fastening your seat belt:

Combination retractor type seat belts

are installed in the rear seat positions to

help accommodate the installation of

Child Restraint System. Although a combination

retractor is also insta

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles