Kia Sportage: Assembly - Replacing body panel

Assembly

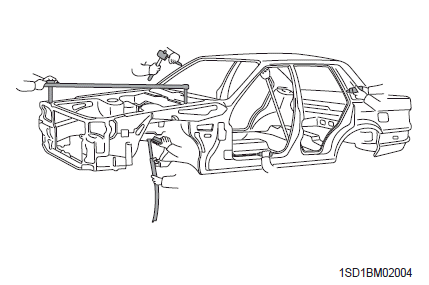

1. Checking welding and fitting in advance

- When assembling a new part, measure the dimensions of each part according to the body dimensions given in Section 31, and set part to the reference dimensions.

- Prior to final welding, check the fit of all related parts.

2. Selecting number of welding points

Spot welding : Multiply the original number of factory welds by 1.3 times

Plug welding : Same number as original number of factory welds

Notice

- Plug welding should be done using a carbon arc welding machine.

- Brazing should be done only on areas that were originally brazed at the factory.

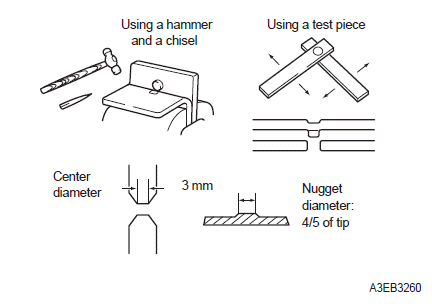

3. Caution when spot welding

- Do a test welding on a piece of material of the same type and thickness as the part to be welded and proceed if test weld is good.

- Before spot welding, check if welding debris, oil or

paint is present on the area where surfaces meet.

Clean or sand as necessary.

- The tip of the spot welding machine should be maintained to a minimum tolerance of 3 mm. Also let area cool after 5 or 6 welds to minimize problems caused by excessive heat.

4. Cutting and welding an assembled area

To align a roof panel and a center pillar together for butt welding, temporarily fasten a steel flange to the roof panel and then apply the new center pillar panel.

Remove the flange when final welding is done.

5. Finishing after welding

- Grind any areas that were plug welded or butt welded using a disk grinder. Grind carefully to avoid removing too much material. This degrades the strength of the weld.

- Finish areas that have been brazed by applying body filler then smooth the area with a flexible file and sander.

6. Applying anti-rust agent and body sealer

After coating the surface with anti-rust agent, apply body sealer where necessary.

Notice

- Apply body sealer before assembly.

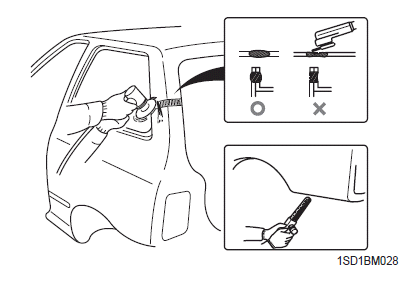

7. Anti-rust treatment

Apply anti-rust agent to inside of doors and sills by spraying through access holes provided.

READ NEXT:

Fender apron panel assembly

Fender apron panel assembly

Welding part

Setion

Cowl panel assembly

Welding part

Section

Dash panel assembly

Welding part

Section

Center floor panel assembly

Welding part

Section

Re

Body dimensions

Body dimensions

Body dimension indications

Projected dimensions

The projected dimension indicates a dimension from a reference point on the

body. (Height may be different in some

cases).

Straight-line dimension

Waterproof and rustproof

Waterproof and rustproof

Sealing

To waterproof and rustproof the vehicle, apply sealer on assembled area of

the body panel and on any areas in

contact with the body, such as doors (inner/outer), hood (inner/outer), and ta

SEE MORE:

Engine compartment

Engine compartment

Smartstream G2.5 GDi

* The actual engine room in the vehicle may differ from the illustration.

Engine coolant reservoir

Brake fluid reservoir

Air cleaner

Engine oil filler cap

Engine oil dipstick

Windshield washer fluid reservoir

Fuse box

Negative battery terminal

Description and Operation

Description and Operation

Limitations Of The Navigation system

GPS Signal Reception State

As the GPS satellite frequency is received/transmitted in straight lines,

reception may not work if hiding devices are

placed on or near the GPS antenna or when traveling though the following

locations.

Tunnels

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles