Kia Sportage: Disassembling spot welded area

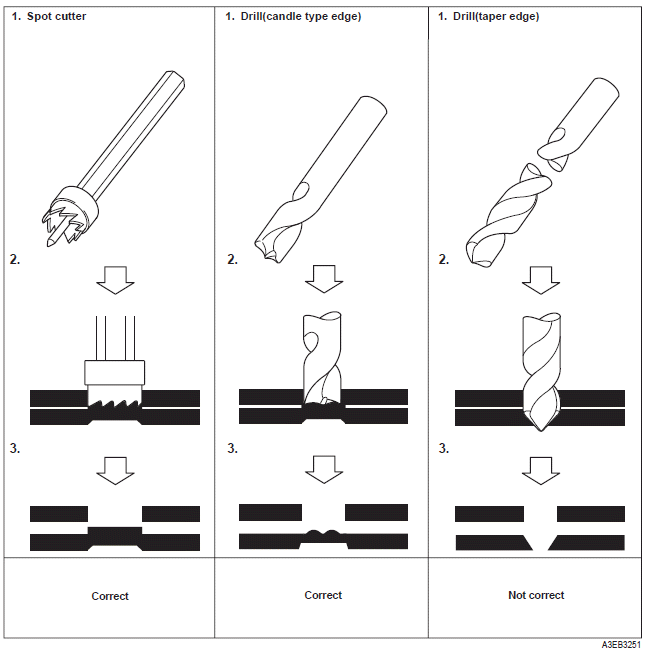

Most body parts are spot welded. In order to disassemble the damaged area, it is best to disassemble the spot welded area from the body frame using a spot cutter or candle type edge drill bit. Do not use a drill bit with a tapered edge. Center punch middle of spot weld to insure the entire spot weld will be removed.

Assembling a new body frame

The efficiency of the transmission and load distribution are determined by many complicated factors such as thickness of plate, shape and size of a cross section, damage of parts, variance of joints, welding method, and/or welding locations. Therefore, a new part should be fitted to the body frame using the proper procedures to avoid reducing the strength of the body.

Determining a welding method

It is extremely important that appropriate welding methods, which don't reduce the original strength and durability of the body be used when making repairs, Try to use either spot welding or carbon arc (plug) welding, Do not braze any body components other than the ones brazed at the factory. Do not use an oxy-acetylene torch for welding.

READ NEXT:

Spot welding

Spot welding

1. Commercial spot welding machines do not perform

as well as the machines used in the manufacturing

process. When spot welding, increase the number

of spot welds by 30% (1.3 times the original num

Disassembly - Replacing body panel

Disassembly - Replacing body panel

Disassembly

1. Body measurement

Before disassembling, measure the damaged area

according to the dimensions supplied in Body

Dimension, Section 31. If deformation is present,

use a frame str

Preparation for assembly - Replacing body panel

Preparation for assembly - Replacing body panel

Preparation for assembly

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark. Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any

SEE MORE:

Repair procedures | Components and Components Location

Repair procedures | Components and Components Location

Component Replacement After Deployment

NOTE

Before doing any SRS repairs, use the GDS Pro to check for DTCs. Refer to the Diagnostic Trouble Code list for repairing of the related DTCs.

When the front airbag(s) deployed after a collision, replace the following items.

SRSCM

Deployed

Rail Pressure Sensor (RPS)

Rail Pressure Sensor (RPS)

Description and Operation

Description

Rail Pressure Sensor (RPS) is installed on the delivery pipe and measures the

instantaneous fuel pressure in the delivery pipe. The sensing element

(Semiconductor element) built in the sensor converts the pressure to voltage

signal. By using this si

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles