Kia Sportage: Inspection - Repair procedures

Connecting Rod

1. Check the connecting rod end play.

Using a feeler gauge, measure the end play while moving the connecting rod back and forth.

End play:

Standard : 0.10 ~ 0.25mm (0.0039 ~ 0.0098in.)

Limit: 0.35mm (0.0138in.)

- If out-of-tolerance, install a new connecting rod.

- If still out-of-tolerance, replace the crankshaft.

2. Check the connecting road bearing oil clearance.

- Check the matchmarks on the connecting rod and cap are aligned to ensure correct reassembly.

- Remove 2 connecting rod cap bolts.

- Remove the connecting rod cap and bearing half.

- Clean the crank pin and bearing.

- Place plastigage across the crank pin.

- Reinstall the bearing half and cap, and torque the bolts.

Tightening torque 17.7~21.6N.m (1.8~2.2kgf.m, 13.0-15.9lb-ft) + 88~92º

NOTE

Do not turn the crankshaft.

- Remove 2 bolts, connecting rod cap and bearing half.

- Measure the plastigage at its widest point.

Standard oil clearance 0.031 ~ 0.045mm (0.00122 ~ 0.00177in.)

- If the plastigage measures too wide or too narrow, remove the upper half of the bearing, install a new, complete bearing with the same color mark (select the color as shown in the next column), and recheck the clearance.

CAUTION

Do not file, shim, or scrape the bearings or the caps to adjust clearance.

- If the plastigage shows the clearance is still incorrect, try the next larger or smaller bearing (the color listed above or below that one), and check clearance again.

NOTE

If the proper clearance cannot be obtained by using the appropriate larger or smaller bearings, replace the crankshaft and start over.

CAUTION

If the marks are indecipherable because of an accumulation of dirt and dust, do not scrub them with a wire brush or scraper. Clean them only with solvent or detergent.

Connecting Rod Identification Mark

Connecting Rod Specifications

Crankshaft Pin Identification Mark

NOTE

Conform to read stamping order as shown arrow direction from #1.

Crankshaft Specifications

Connecting Rod Bearing Identification Mark

Connecting Rod Bearing Specifications

Selection Chart For Connecting Rod Bearings

3. Inspect the connecting rods.

- When reinstalling, make sure that cylinder numbers put on the connecting

rod and cap at disassembly match.

When a new connecting rod is installed, make sure that the notches for holding the bearing in place are on the same side.

- Replace the connecting rod if it is damaged on the thrust faces at either end. Also if step wear or a severely rough surface of the inside diameter of the small end is apparent, the rod must be replaced as well.

- Using a connecting rod aligning tool, check the rod for bend and twist. If the measured value is close to the repair' limit, correct the rod by a press. Any connecting rod that has been severely bent or distorted should be replaced.

Allowable bend of connecting rod : 0.05mm (0.0020 in.) or less for 100mm (3.94 in.)

Allowable twist of connecting rod : 0.10mm (0.0039 in.) or less for 100mm (3.94 in.)

Crankshaft

1. Check the crankshaft bearing oil clearance.

- To check main bearing-to-journal oil clearance, remove the main caps and bearing halves.

- Clean each main journal and bearing half with a clean shop tower.

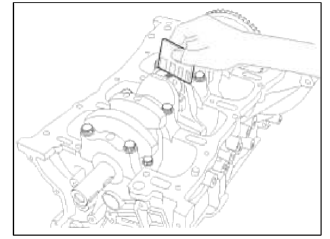

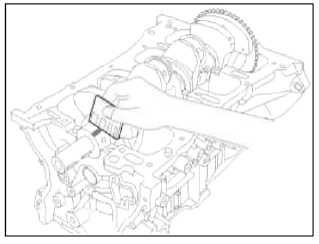

- Place one strip of plastigage across each main journal.

- Reinstall the bearings and caps, then torque the bolts.

Tightening torque : 14.7N.m (1.5kgf.m, 10.8lb-ft) + 27.5~31.4N.m (2.8~3.2kgf.m, 20.3~23.1lb-ft) + 120~125º

NOTE

Do not turn the crankshaft.

- Remove the cap and bearing again, and measure the widest part of the plastigage.

Standard oil clearance 0.020 ~ 0.038mm (0.00079 ~ 0.00150in.)

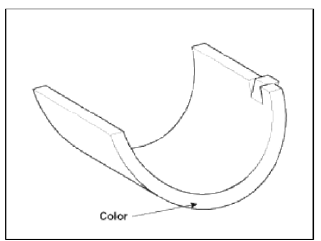

- If the plastigage measures too wide or too narrow, remove the upper half of the bearing, install a new, complete bearing with the same color mark (select the color as shown in the next column), and recheck the clearance.

CAUTION

Do not file, shim, or scrape the bearings or the caps to adjust clearance.

- If the plastigage shows the clearance is still incorrect, try the next larger or smaller bearing (the color listed above or below that one), and check clearance again.

NOTE

If the proper clearance cannot be obtained by using the appropriate larger or smaller bearings, replace the crankshaft and start over.

CAUTION

If the marks are indecipherable because of an accumulation of dirt and dust, do not scrub them with a wire brush or scraper. Clean them only with solvent or detergent.

Crankshaft Bore Identification Mark

Letters have been stamped on the block as a mark for the size of each of the 5 main journal bores.

Use them, and the numbers or bar stamped on the crank (marks for main journal size), to choose the correct bearings.

Cylinder Block Specifications

Crankshaft Journal Identification Mark

NOTE

Conform to read stamping order as shown arrow direction from #1.

Crankshaft Specifications

Crankshaft Bearing Identification Mark

Crankshaft Bearing Specifications

Selection Chart For Crankshaft Bearings

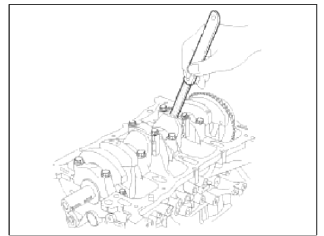

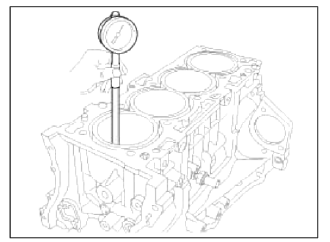

2. Check crankshaft end play.

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

End play

Standard: 0.07 ~ 0.25mm (0.0028 ~ 0.0098in.)

Limit: 0.30mm (0.0118in.)

If the end play is greater than maximum, replace the thrust bearings as a set.

Thrust bearing thickness: 1.925 ~ 1.965mm (0.07579 ~ 0.07736in.)

3. Inspect main journals and crank pins.

Using a micrometer, measure the diameter of each main journal and crank pin.

Main journal diameter: 51.942 ~ 51.960mm (2.04496 ~ 2.04567in.)

Crank pin diameter: 47.954 ~ 47.972mm (1.88795 ~ 1.88866in.)

Cylinder Block

1. Remove gasket material.

Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

2. Clean cylinder block.

Using a soft brush and solvent, thoroughly clean the cylinder block.

3. Inspect top surface of cylinder block for flatness.

Using a precision straight edge and feeler gauge, measure the surface contacting the cylinder head gasket for warpage.

Flatness of cylinder block gasket surface

Standard: Less than 0.05mm (0.0019in.) for all Less than 0.02 (0.0007in.) for 100mm (3.9370in.) x 100mm (3.9370in.)

4. Inspect cylinder bore diameter.

Visually check the cylinder for vertical scratchs.

If deep scratches are present, replace the cylinder block.

5. Inspect cylinder bore diameter.

Using a cylinder bore gauge, measure the cylinder bore diameter at position in the thrust and axial directions.

Standard diameter 86.00 ~ 86.03mm (3.3858 ~ 3.3870in.)

NOTE

Measurement position points (from the bottom of the cylinder block): 110.7mm(4.3582in.)/160mm(6.2992in.)/210mm(8.2677in.)

6. Check the cylinder bore size code on the cylinder block.

Cylinder Bore Inner Diameter

7. Check the piston size code on the piston top face.

NOTE

Stamp the grade mark of basic diameter with rubber stamp.

Piston Outer Diameter

8. Select the piston related to cylinder bore class.

Clearance : 0.020 ~ 0.040mm (0.00079 ~ 0.00157in.)

Piston And Rings

1. Clean piston

- Using a gasket scraper, remove the carbon from the piston top.

- Using a groove cleaning tool or broken ring, clean the piston ring grooves.

- Using solvent and a brush, thoroughly clean the piston.

NOTE

Do not use a wire brush.

2. The standard measurement of the piston outside diameter is taken 17mm (0.67in.) from the top land of the piston.

Standard diameter 85.970 ~ 86.000mm (3.3846 ~ 3.3858in.)

3. Calculate the difference between the cylinder bore diameter and the piston diameter.

Piston-to-cylinder clearance 0.020 ~ 0.040mm (0.00079 ~ 0.00157in.)

4. Inspect the piston ring side clearance.

Using a feeler gauge, measure the clearance between new piston ring and the wall of the ring groove.

Piston ring side clearance

Standard

No.1 : 0.050 ~ 0.080mm (0.00197 ~ 0.00315m.)

No.2 : 0.040 ~ 0.080mm (0.00157 ~ 0.00315m.)

Oil ring : 0.020 ~ 0.055mm (0.00079 ~ 0.00217m.)

Limit

No.1 : 0.100mm(0.00394in.)

No.2 : 0.100mm (0.00394in.)

Oil ring : 0.100mm (0.00394in.)

If the clearance is greater than maximum, replace the piston.

5. Inspect piston ring end gap.

To measure the piston ring end gap, insert a piston ring into the cylinder bore. Position the ring at right angles to the cylinder wall by gently pressing it down with a piston. Measure the gap with a feeler gauge. If the gap exceeds the service limit, replace the piston ring. If the gap is too large, recheck the cylinder bore diameter against the wear limits. If the bore is over the service limit, the cylinder block must be replaced.

Piston ring end gap

Standard

No.1 : 0.15 ~ 0.30mm (0.0059 ~ 0.0118in.)

No.2 : 0.37 ~ 0.52mm (0.0145 ~ 0.0204in.)

Oil ring : 0.20 ~ 0.50mm (0.0079 ~ 0.0197in.)

Limit

No.1 : 0.60mm (0.0236in.)

No.2 : 0.70mm (0.0275in.)

Oil ring : 0.80mm (0.0315in.)

Piston Pins

1. Measure the diameter of the piston pin.

Piston pin diameter

21.997 ~ 22.000mm (0.86602 ~ 0.86614in.)

2. Measure the piston pin-to-piston clearance.

Piston pin-to-piston clearance 0.003 ~ 0.010mm (0.00012 ~ 0.00039in.)

3. Check the difference between the piston pin diameter and the connecting rod small end diameter.

3. Check the difference between the piston pin diameter and the connecting rod small end diameter.

Piston pin-to-connecting rod interference 0.005 ~ 0.014mm (0.00020 ~ 0.00055in.)

READ NEXT:

Reassembly - Repair procedures

Reassembly - Repair procedures

NOTE

Thoroughly clean all parts to assembled.

Before installing the parts, apply fresh engine oil to all sliding

and rotating surfaces.

Replace all gaskets, O-rings and oil seals with new p

Coolant

Coolant

Repair procedures

Refilling And Bleeding

WARNING

Never remove the radiator cap when the engine is hot. Serious scalding

could be caused by hot fluid under high

pressure escaping from the radiato

SEE MORE:

Repair procedures | Components and Components Location | Transaxle Control Module (TCM)

Repair procedures | Components and Components Location | Transaxle Control Module (TCM)

Adjustment

TCM Learning

When shift shock is occurred or parts related with the transaxle are replaced. TCM learning should be performed.

In the following case, TCM learning is required.

Transaxle assembly replacement

TCM replacement

TCM upgrading

1. TCM learning conditi

Description and Operation, Specifications, Troubleshooting, Schematic Diagrams | Components and Components Location

Description and Operation, Specifications, Troubleshooting, Schematic Diagrams | Components and Components Location

Description and Operation

Description

Emissions Control System consists of thee major systems.

The Crankcase Emission Control System prevents blow-by gas from releasing into the atmosphere. This system recycles gas back into the intake manifold (Closed Crankcase Ventilation Type)

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles