Kia Sportage: Exhaust Manifold

Components and Components Location

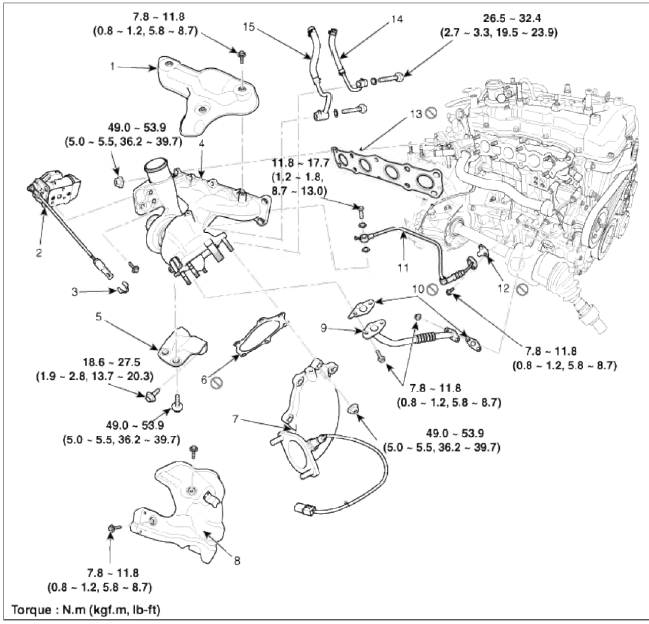

Components

- Hear protector

- EWGA (Electric Waste Gate Actuator)

- C-ring

- Turbo manifold module

- Turbocharger stay

- Turbo adapter gasket

- Turbo adapter

- Turbo adapter heat protector

- Oil drain pipe assembly

- Turbocharger oil drain gasket

- Oil feed pipe & hose assembly

- Oil drain gasket

- Exhaust manifold gasket

- Turbocharger water feed hose

- Turbocharger water drain hose

Repair procedures

Removal and Installation

1. Remove the engine cover.

2. Disconnect the battery negative terminal (A).

Tightening torque

4.0 ~ 6.0N.m (0.4 ~ 0.6kgf.m, 3.0 ~ 4.4lb-ft)

3. Disconnect the oxygen sensor connector (A).

4. Remove the exhaust manifold heat protectors (A).

Tightening torque: 7.8 ~ 11.8N.m (0.8 ~ 1.2kgf.m, 5.8 ~ 8.7lb-ft)

CAUTION

Check that engine is cool enough to work.

5. Remove the front muffler (A).

Tightening torque: 39.2 ~ 58.8 N.m (4.0 ~ 6.0 kgf.m, 28.9 ~ 43.4 lb-ft)

6. Support the sub frame (A) with a floor jack, and then remove the sub frame mounting bolts and nuts.

Tightening torque: 176.5 ~ 196.1 N.m (18.0 ~ 20.0 kgf.m, 130.2 ~ 144.7 lb-ft)

NOTE

- After removing the sub frame mounting bolt, the engine and transaxle assembly may fall downward, and so support them securely with floor jack.

- Verify that the hoses and connectors are disconnected before removing the engine and transaxle assembly.

7. Disconnect the turbocharger water feed hose (A) and the water drain hose (B).

8. Remove the turbocharger stay (A) and then disconnect the oil drain pipe (B) and gasket.

Tightening torque:

Bolts (C): 18.6 ~ 27.5N.m (1.9 ~ 2.8kgf.m, 13.7 ~ 20.3lb-ft)

Bolts (D ): 49.0 ~ 53.9N.m (5.0 ~ 5.5kgf.m, 36.2 ~ 39.8lb-ft)

Bolts (E ): 7.8 ~ 11.8N.m (0.8 ~ 1.2kgf.m, 5.8 ~ 8.7lb-ft)

NOTE

When installing, clean the gasket surface and replace the oil drain pipe gasket with new one.

9. Disconnect the oil feed pipe (A) and then remove the turbo manifold module (B).

Tightening torque

Oil feed pipe eye bolt: 11.8 ~ 17.7N.m (1.2 ~ 1.8kgf.m, 8.7 ~ 13.0lb-ft)

Turbo manifold module nuts: 49.0 ~ 53.9N.m (5.0 ~ 5.5kgf.m, 36.2 ~ 39.7lb-ft)

CAUTION

When installing the oil feed pipe & hose, make sure the stopper (A) don't touch the compressor housing.

Be careful not to bend or crush the pipe & hose.

NOTE

When installing, be sure the eye bolt о-rings are completely seated in both hole of oil feed pipe.

NOTE

When installing, replace with a new gasket.

When installing the turbo manifold module, tighten the nuts with pre-torque first, and then tighten the nuts with specified torque in the sequence shown.

10. Remove the turbo manifold module gasket (A).

11. Installation is reverse order of removal.

NOTE

- Always use the new turbo manifold module and turbo adapter gaskets when replacing.

- Always use a new turbocharger nuts and, exhaust manifold nuts when it is removed.

- Take care whether the oil feed pipe & hose assembly is interfered with turbo manifold module and any surrounding parts.

- If the oil feed pipe & hose is damaged, engine oil is not supplied sufficiently to the turbocharger then it may damage the turbocharger. If the oil drain pipe & hose is damaged and clogged, engine oil is not drained smoothly then it may cause oil leaks from the turbocharger. Be care fill the oil feed pipe & hose not to damage. (bent, crushed, tom or cracked).

READ NEXT:

Turbo Charger

Turbo Charger

Components and

Components Location

Components

Turbine housing

Turbine inlet

Turbine outlet

Compressor housing

Compressor inlet

Compressor outlet

Center housing

EWGA (Electr

Intercooler

Intercooler

Components and

Components Location

Components

Recirculation hose

Intercooler inlet hose & pipe

assembly

Intercooler outlet hose & pipe

assembly

Intercooler mounting bra

Muffler

Muffler

Components and Components

Location

Components

Front muffler

Catalytic converter

Center muffler

Main muffler

Gasket

Repair procedures

Removal and Installation

1. Remove the f

SEE MORE:

Daytime Running Light (DRL)

Daytime Running Light (DRL)

The Daytime Running Light (DRL) can

make it easier for others to see the front

of your vehicle during the day.

The DRL can be helpful in many different

driving conditions, and it is especially

helpful after dawn and before sunset.

The DRL will turn the dedicated lamp

OFF when:

The hea

Body Side Moldings

Body Side Moldings

Repair procedures

Replacement

Roof Rack Replacement

CAUTION

When prying with a flat-tip screwdriver, wrap it with protective

tape, and apply protective tape around the

related parts, to prevent damaged.

Put on gloves to protect your hands.

Take care not to scratch the body surf

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles