Kia Sportage: Battery

Description and Operation

Description

1. The maintenance-free battery is, as the name implies, totally maintenance free and has no removable battery cell caps.

2. Water never needs to be added to the maintenance-free battery.

3. The battery is completely sealed, except for small vent holes in the cover.

NOTE

After disconnecting then reconnecting the battery negative cable, reset some parts that require the reset procedures. (Refer to BE group - General Information)

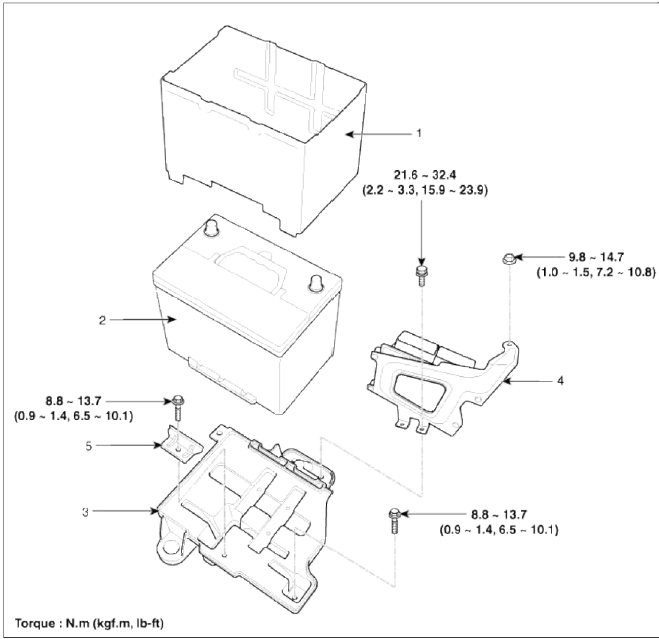

Components and Components Location

Components

- Battery insulation pad

- Battery

- Battery tray

- ECM & bracket assembly

- Battery mounting bracket

Repair procedures

Removal and Installation

1. Remove the battery.

- Disconnect the battery negative terminal (A)

Tightening torque: 4.0 ~ 6.0N.m (0.4 ~ 0.6kgf.m, 3.0 ~ 4.4lb-ft)

- Disconnect the battery positive terminal (B).

Tightening torque: 7.8 ~ 9.8 N.m (0.8 ~ 1.0 kgf.m, 5.8 ~ 7.2 lb-ft)

- Remove the battery insulation pad (C).

- Remove the battery mounting bracket (D), and the battery (E).

Tightening torque: Bracket bolt: 8.8 ~ 13.7 N.m (0.9 ~ 1.4 kgf.m, 6.5 ~ 10.1 lb-ft)

2. Remove the air duct and air cleaner assembly. (Refer to EM group).

3. Remove the ECM (A) after disconnecting the connectors (B). (Refer to FL group

4. Remove the battery tray (A).

Tightening torque: 8.8 ~ 13.7 N.m (0.9 ~ 1.4 kgf.m, 6.5 ~ 10.1 lb-ft)

5. Installation is the reverse order of removal.

CAUTION

When installing the battery, fix the mounting bracket on the tray correctly.

Inspection

Battery Diagnostic Flow

Vehicle parasitic current inspection

1. Turn the all electric devices OFF, and then turn the ignition switch OFF.

2. Close all doors except the engine hood, and then lock all doors.

- Disconnect the hood switch connector.

- Close the trunk lid.

- Close the doors or remove the door switches.

3. Wait a few minutes until the vehicle's electrical systems go to sleep mode.

NOTE

For an accurate measurement of a vehicle parasitic current, all electrical systems should go to sleep mode.

(It takes at least one how or at most one day.) However, an approximate vehicle parasitic current can be measured after 10-20 minutes.

4. Connect an ammeter in series between the battery (-) terminal and the ground cable, and then disconnect the clamp from the battery (-) terminal slowly.

CAUTION

Be careful that the lead wires of an ammeter do not come off from the battery (-) terminal and the ground cable to prevent the battery from being reset. In case the battery is reset, connect the battery cable again, and then start the engine or turn the ignition switch ON for more than 10 sec. Repeat the procedure from No. 1.

To prevent the battery from being reset during the inspection,

- Connect a jump cable between the battery (-) terminal and the ground cable.

- Disconnect the ground cable from the battery (-) terminal.

- Connect an ammeter between the battery (-) terminal and the ground cable.

- After disconnecting the jump cable, read the current value of the ammeter.

5. Read the current value of the ammeter.

- If the parasitic current is over the limit value, search for abnormal circuit by removing a fuse one by one and checking the parasitic current.

- Check the parasitic current again, and search for suspected writ by removing a unit connected with the abnormal circuit one by one.

Limit value (after 10-20 min.) : Below 50mA

Cleaning

1. Make sure the ignition switch and all accessories are in the OFF position.

2. Disconnect the battery cables (negative first).

3. Remove the battery from the vehicle.

CAUTION

Care should be taken in the event the battery case is cracked or leaking, to protect your skin from the electrolyte.

Heavy rubber gloves (not the household type) should be wore when removing the battery.

4. Inspect the battery tray for damage caused by the loss of electrolyte. If acid damage is present, it will be necessary to clean the area with a solution of clean warm water and baking soda. Scrub the area with a stiff brush and wipe off with a cloth moistened with baking soda and water.

5. Clean the top of the battery with the same solution as described above.

6. Inspect the battery case and cover for cracks. If cracks are present, the battery must be replaced.

7. Clean the battery posts with a suitable battery post tool.

8. Clean the inside surface of the terminal clamps with a suitable battery cleaning tool. Replace damaged or frayed cables and broken terminal clamps.

9. Install the battery in the vehicle.

10. Connect the cable terminals to the battery post, making sure tops of the terminals are flush with the tops of the posts.

11. Tighten the terminal nuts securely.

12. Coat all connections with light mineral grease after tightening.

CAUTION

When batteries are being charged, an explosive gas forms beneath the cover of each cell. Do not smoke near batteries being charged or which have recently been charged. Do not break live circuit at the terminals of batteries being charged.

A spark will occur when the circuit is broken. Keep open flames away from battery.

READ NEXT:

Battery Sensor

Battery Sensor

Description and Operation

Description

Vehicles have many control units that use more electricity. These units

control their own system based on information

from diverse sensors. It is impor

Description and Operation | Repair procedures

Description and Operation | Repair procedures

Description

The starting system includes the battery, starter, solenoid switch, ignition switch, inhibitor switch (A/T), clutch pedal switch (M/T), ignition lock switch, connection wires and t

SEE MORE:

Consumer Assistance (U.S. only)

Consumer Assistance (U.S. only)

Roadside Assistance is provided on all

new current model year Kia Vehicles

from the date the vehicle is delivered to

the first retail buyer or otherwise put into

use (inservice date), whichever is earlier,

for a period of 60 months or 60,000

miles, whichever is earlier, subject to the

terms,

Spot welding

Spot welding

1. Commercial spot welding machines do not perform

as well as the machines used in the manufacturing

process. When spot welding, increase the number

of spot welds by 30% (1.3 times the original number

of welds).

2. When spot welding, weld in the middle of the joint.

Spot welding on the

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles