Kia Sportage: Balance Shaft & Oil Pump

Components and Components Location

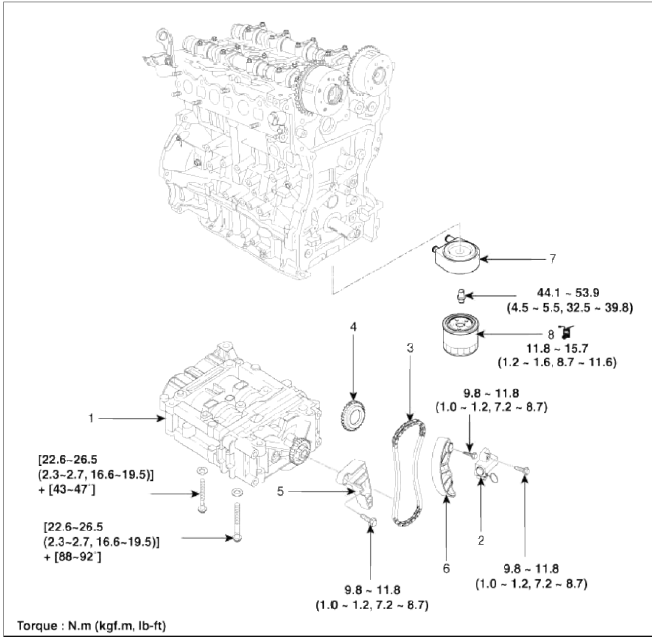

Components

- Balance shaft & oil pump assembly

- Balance shaft chain tensioner

- Balance shaft chain

- Balance shaft chain sprocket

- Balance shaft chain guide

- Balance shaft chain tensioner arm

- Oil cooler

- Oil filter

Repair procedures

Removal

1. Remove the timing chain. (Refer to Timing system in this group)

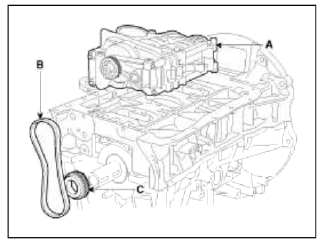

2. Install a stopper pin (A) after compressing the balance shaft chain tensioner.

3. Remove the balance shaft chain hydraulic tensioner (B).

4. Remove the balance shaft chain tensioner arm (C).

5. Remove the balance shaft chain guide (D).

6. Remove the balance shaft & oil pump module (A) and balance shaft chain (B) and the sprocket (C).

CAUTION

Do not disassemble the balance shaft & oil pump module.

Installation

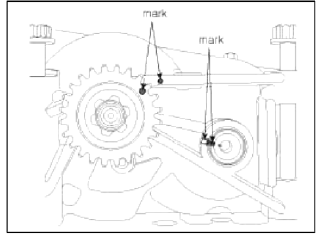

1. The key of crankshaft should be aligned with the mating face of main bearing cap. As a result of this, the piston of No.1 cylinder is placed at the top dead center on compression stroke.

2. Confirm the balance shaft & oil pump module timing mark.

Timing marks to be visually aligned with centers of adjacent cast timing notches.

З. Install the balance shaft & oil pump module (A) with the chain (B) and the sprocket (C).

NOTE

The timing marks of balance shaft & oil pump module sprocket and crankshaft sprocket should be matched with the tuning marks (color link) of balance shaft chain.

Tightening order

- Tighten the bolts in order number as shown with seating torque 26.4 N.m (3.0kgf.m, 21.7 lb-ft) and then loosen the bolts as reverse tightening order. (6-5-4-3-2-1).

- Using the SST (09221-4A000), tighten the bolts as specified tightening order in same increments as follows.

Tightening torque:

Bolts (A) (M9x181.5): 22.6-26.5N.m (2.3~2.7kgf.m, 16.6~19.5lb-ft) + 88~92º

Bolts (B) (M9x95): 22.6~26.5N.m (2.3~2.7kgf.m, 16.6~19.5lb-ft) + 43~47º

4. Install the balance shaft chain guide (D).

Tightening torque: 9.8 ~ 11.8N.m (1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb-ft)

5. Install the balance shaft chain tensioner arm (C).

Tightening torque: 9.8 ~ 11.8N.m (1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb-ft)

6. Install the balance shaft chain hydraulic tensioner (B) then remove the stopper pin (A).

Tightening torque: 9.8 ~ 11.8N.m (1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb-ft)

7. Confirm the timing marks.

8. Install the timing chain. (Refer to Timing system in this group)

READ NEXT:

Oil Cooler | Oil Pressure Switch

Oil Cooler | Oil Pressure Switch

Repair procedures

Removal

1. Loosen the drain plug, and drain the coolant. Remove the radiator cap to speed draining.

2. Disconnect the oil cooler coolant hoses (A).

З. Remove the oil f

SEE MORE:

Limitations of Reverse Parking

Collision-Avoidance Assist

Limitations of Reverse Parking

Collision-Avoidance Assist

Reverse Parking Collision-Avoidance

Assist may not assist braking or warn the

driver even if there are pedestrians or

objects under the following circumstances:

Any non-factory equipment or accessory

is installed

Your vehicle is unstable due to an

accident or other causes

Bumper heigh

Components and Components Location

Components and Components Location

Components Location

Converter housing

Automatic transaxle case

Rear cover

Valve body cover

Manual control lever

Air breather hose

Inhibitor switch

Solenoid valve

connector

Repair procedures

Removal

1. Remove the following items;

Engine cover (A).

Air cleaner asse

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles