Kia Sportage: Alternator

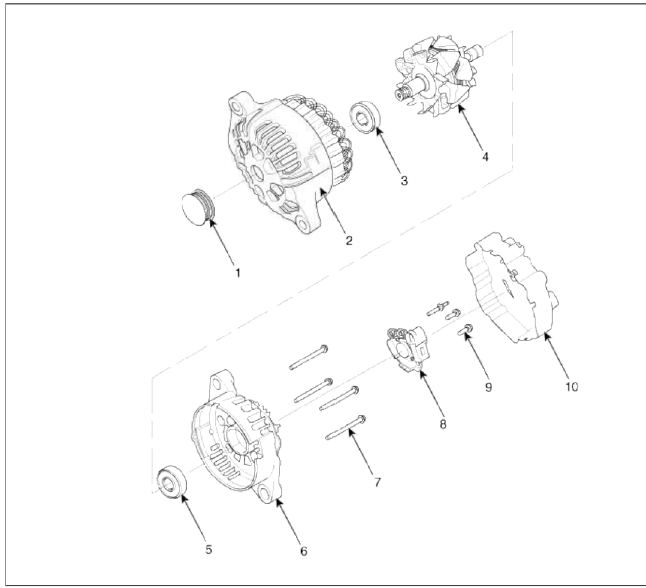

Components and Components Location

Components

- Pulley

- Front bracket

- Front bearing

- Rotor

- Rear bearing

- Rear bracket

- Though bolt

- Regulator assembly

- Regulator bolt

- Rear cover

Repair procedures

Removal and Installation

1. Disconnect the battery negative terminal first, then the positive terminal.

Tightening torque:

(+) terminal: 7.8 ~ 9.8N.m (0.8 ~ 1.0kgf.m, 5.8 ~ 7.2lb-ft)

(-) terminal: 4.0 ~ 6.0N.m (0.4 ~ 0.6kgf.m. 3.0 ~ 4.4lb-ft)

2. Disconnect the Ð/С compressor switch connector (A) the alternator connector (B), and the cable from alternator "B" terminal (C).

3. Remove the drive belt (A) after turning the drive belt tensioner (B) counterclockwise.

4. Pull out the through bolt and then remove the alternator (A).

Tightening torque: 49.0 ~ 63.7N.m (5.0 ~ 6.5kgf.m, 36.2 ~ 47.0lb-ft)

5. Installation is the reverse order of removal.

Disassembly

1. Remove the alternator cover (A) using a screw driver after loosening the nuts (B).

2. Remove the slip ring guide (A) and then loosen the mounting bolts and disconnect the brush holder assembly (B).

3. Remove the pulley (A) using the SST (09373-27000) (B).

4. Loosen the 4 through bolts (A).

5. Disconnect the rotor (A) and cover (B).

6. Reassembly is the reverse order of disassembly.

Inspection

Inspect Rotor

1. Check that there is continuity between the slip lings (C).

2. Check that there is no continuity between the slip lings and the rotor (B) or rotor shaft (A).

3. If the rotor fails either continuity check, replace the alternator.

Inspect Stator

1. Check that there is continuity between each pair of leads (A).

2. Check that there is no continuity between each lead and the coil core.

3. If the coil fails either continuity check, replace the alternator.

READ NEXT:

Battery

Battery

Description and Operation

Description

1. The maintenance-free battery is, as the name implies, totally maintenance

free and has no removable battery cell

caps.

2. Water never needs to be

Battery Sensor

Battery Sensor

Description and Operation

Description

Vehicles have many control units that use more electricity. These units

control their own system based on information

from diverse sensors. It is impor

SEE MORE:

How to reset the power liftgate

How to reset the power liftgate

If the battery has been discharged or

disconnected, or if the related fuse has

been replaced or disconnected, for the

power liftgate to operate normally, reset

the power liftgate as follow:

Make sure the gear is shifted to P

(Park) position.

Press and hold the Power liftgate

open/close

Ignition System

Ignition System

Description and Operation

Description

Ignition timing is controlled by the electronic control ignition timing

system. The standard reference ignition timing

data for the engine operating conditions are preprogrammed in the memory of the

ECM (Engine Control Module).

The engine operati

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles