Kia Sportage: Repair procedures | Canister

Inspection

[System Inspection]

1. Disconnect the vapor hose from the intake manifold and connect a vacuum pump to the nipple on the intake manifold.

- At Cold Engine [Engine Coolant Temperature < 60ºC(140ºF) ]

2. Check the following points with applied vacuum at the purge control solenoid valve (PCSV).

- At Warmed Engine [Engine Coolant Temperature > 80ºC(176ºF) ]

![[PCSV Inspection]](images/books/1921/16/index%20143.png)

[PCSV Inspection]

1. Turn ignition switch OFF and disconnect the negative (-) battery cable.

2. Disconnect the PCSV connector (A).

3. Disconnect the vapor hose (B) which is connected to the intake manifold from the PCSV.

4. After connecting a vacuum pump to the nipple, apply vacuum.

5. With the PCSV control line grounded, check the valve operation with battery voltage applied to the PCSV (Open) and removed (Closed).

6. Measure the coil resistance of the PCSV.

Specifications: 19.0 ~ 22.0Ω [20ºC (68ºF) ]

[EVAP Leakage Test]

1. Select "Evap. Leakage Test".

2. Proceed with the test according to the screen introductions.

Canister

Repair procedures

Removal

1. Remove the fuel tank. (Refer to "Fuel tank" in FL group.)

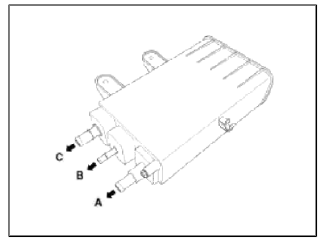

2. Disconnect the vapor tube quick-connector (B) and the ventilation hose (A).

3. Remove the canister in the direction of an arrow after removing the installation screws (C).

Inspection

1. Check for the following items visually.

- Cracks or leakage of the canister.

- Loose connection, distortion, or damage of the vapor hose/tube.

- Canister ↔ Atmosphere

- Canister ↔ Intake Manifold

- Canister ↔ Fuel Tank

Installation

Installation is the reverse of removal.

READ NEXT:

Fuel Filler Cap | Fuel Tank Air Filter

Fuel Filler Cap | Fuel Tank Air Filter

Description and Operation

Description

A ratchet tightening device on the threaded fuel filler cap reduces the chances of incorrect installation, which seals the fuel filler. After the gasket

SEE MORE:

USB charger

USB charger

The USB car charger allows drivers to

charge their digital devices such as

smartphones, and PC tablets.

Front

Plug the cable into the USB port, and

charging will begin.

The USB car charger is available with

either the ACC on or the ignition on. We

recommend you connect the USB port

and

Lane Following Assist operation

Lane Following Assist operation

Lane Following Assist will control and

warn the vehicle by 'Lane Following

Assist' and 'Hands-off warning'.

Lane Following Assist

If the vehicle ahead and/or both lane

markings are detected and your vehicle

speed is below 110 mph (180 km/h),

Lane Following Assist will help

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles