Kia Sportage: Components and Components Location | Repair procedures

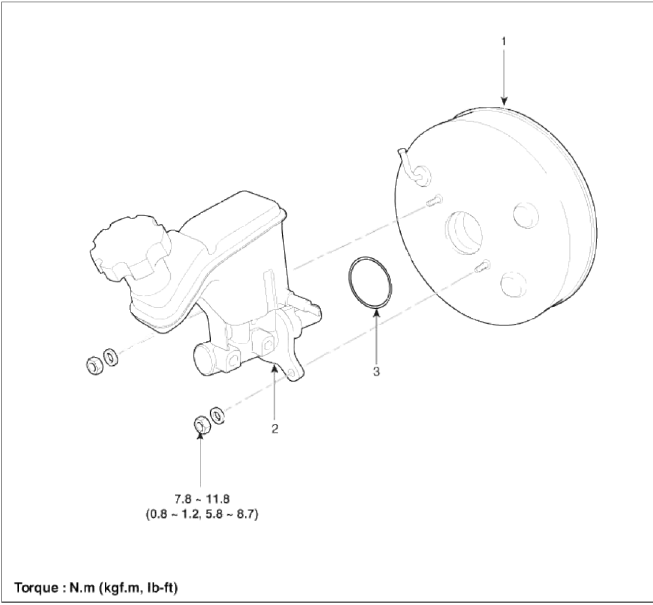

Components (1)

- Brake booster

- Master cylinder assembly

- O-ring

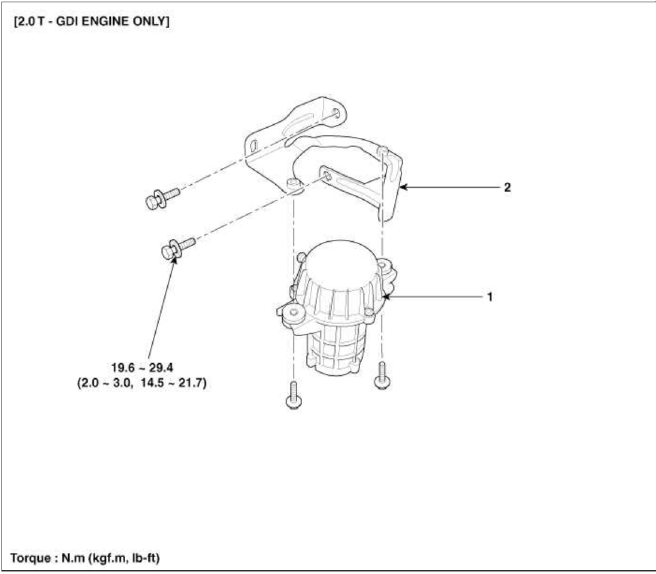

Components (2)

[2.0T - GDI ENGINE ONLY]

- Vacuum pump

- Bracket

Repair procedures

Brake Booster Operating Test

For simple checking of the brake booster operation, carry out the following tests.

1. Run the engine for one or two minutes, and then stop it. If the pedal depresses fully the first time but gradually becomes higher when depressed succeeding times, the booster is operating properly, if the pedal height remains unchanged, the booster is inoperative.

2. With the engine stopped, step on the brake pedal several times.

Then step on the brake pedal and start the engine. If the pedal moves downward slightly, the booster is in good condition. If there is no change, the booster is inoperative.

3. With the engine running, step on the brake pedal and then stop the engine. Hold the pedal depressed for 30 seconds. If the pedal height does not change, the booster is in good condition, if the pedal rises, the booster is inoperative.

If the above three tests are okay, the booster performance can be determined as good.

Even if one of the above three tests is not okay, check the check valve, vacuum hose and booster for malfunction.

Removal

Brake Booster

1. Turn ignition switch OFF and disconnect the negative (-) battery cable.

2. Disconnect the battery terminal and then remove the battery.

3. Disconnect the ECM connector and then ECM and battery tray.

4. Disconnect the vacuum hose (A) from the brake booster.

5. Remove the master cylinder. (Refer to Master cylinder)

6. Remove the snap pin (A) and clevis pin (B).

7. Remove the mounting nuts.

Tightening torque: 16.7 ~ 25.5 N.m (1.7 ~ 2.6 kgf.m, 12.3 ~ 18.8 lb-ft)

8. Remove the brake booster.

Vacuum Pump

1. Turn ignition switch OFF.

2. Remove the under covers (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

3. Disconnect the vacuum hose pump connector (A).

4. Disconnect the vacuum hose (A).

5. Loosen the vacuum pump bracket bolts (A), and then remove vacuum pump and bracket.

Tightening torque: 19.6 ~ 29.4 N.m (2.0 ~ 3.0 kgf.m, 14.5 ~ 21.7 lb-ft)

6. Remove the 2 bolts, and then remove the bracket from vacuum pump.

Inspection

1. Inspect the check valve in the vacuum hose, intensifier and the connecting section.

CAUTION

Do not remove the check valve from the vacuum hose.

2. Check the boot for damage.

Vacuum Pump

1. Check the brake warning lamp in the IGN ON position

NOTE

Brake warning lamp is ON as below conditions.

1. Parking brake warning.

2. Low brake fluid level warning.

3. Low brake vacuum pressure warning.

- Vacuum pump is abnormal condition

- Vacuum pump CAN communication is abnormal condition

- Vacuum switch is abnormal condition

2. Check that the brake warning lamp is ON after the release the parking brake with a sufficient brake fluid level.

If the brake warning lamp is ON, check the below points.

- Is the brake warning lamp ON within 5 seconds after IGN ON? (CAN Timeout Error)

NOTE

CAN Timeout Error; The brake warning lamp is ON when the communication fails more than 2 seconds between vacuum pump and cluster.

- Is the brake warning lamp ON within 45 ~ 55 seconds?

- Is the brake warning lamp ON within 15 ~ 35 seconds after removing the vacuum hose from the brake booster?

Installation

Brake Booster

1. Installation is the reverse of removal.

CAUTION

- Before installing the pin, apply the grease to the joint pin.

- Use a new snap pin whenever installing.

2. Adjust the brake pedal height and free play.

(Refer to Brake pedal height and free play adjustment)

3. After installing, bleed the brake system. (Refer to Brake system bleeding)

Vacuum Pump

1. Installation is the reverse of removal.

2. Tighten the vacuum pump mounting bolts to the specified torque.

READ NEXT:

Master Cylinder

Master Cylinder

Components and Components Location

Components

Reservoir cap

Reservoir'

Grommet

Master

cylinder

Repair procedures

Removal

1. Turn ignition switch OFF and disconnect the n

Brake Line

Brake Line

Components and Components Location

Components

Repair procedures

Removal

1. Disconnect the brake fluid level switch connector, and remove the

reservoir cap.

2. Remove the brake fluid f

SEE MORE:

General Service Information

General Service Information

Protection Of The Vehicle

Always be sure to cover fenders, seats, and floor areas before starting work.

CAUTION

The support rod must be inserted into the hole near the edge of the hood

whenever you inspect the engine

compartment to prevent the hood from falling and causing possible injury.

Specifications, Components and Components Location | Repair procedures

Specifications, Components and Components Location | Repair procedures

Specifications

Specifications

Components and Components Location

Component (1)

<Installation order: A→B→C→D>

Steering column shaft

Lighting switch

Wiper and washer switch

Screw

Clock spring

Component (2)

Lighting (13 p

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles