Kia Sportage: Valve Body

Description and Operation

Description

The valve body is essential to automatic transaxle control and consists of various valves used to control the oil feed from the oil pump. Specifically, these valves consist of pressure regulator valves, oil redirection valves, shift valves, and manual valves. The body also features electronic solenoid valves that ensure smooth gear changes.

Components and Components Location

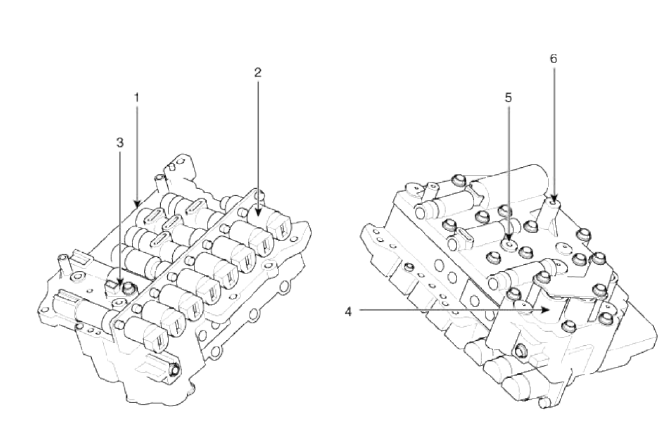

Components Location

- PCV adjust screw

- Solenoid valve

- Oil temperature sensor

- Accumulator

- Low & reverse brake (LR/B) pressure flow hole

- Under drive brake (UD/B) pressure flow hole

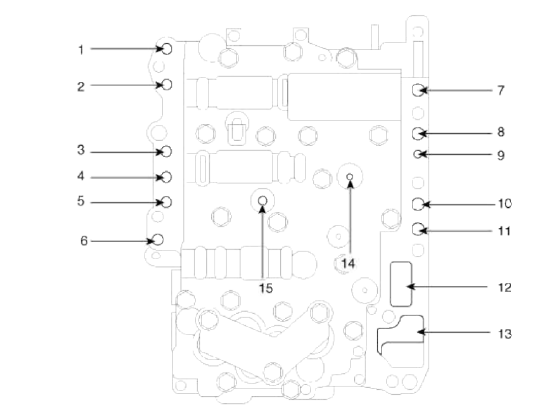

Valve Body Flow

- To cooler

- From cooler

- Lubrication (rear)

- Overdrive pressure

- Reducing pressure (red2)

- Reducing pressure (red1)

- From damper pressure

- To damper pressure

- Lubrication (front)

- 35R clutch pressure

- 26 brake pressure

- From oil pump

- To oil pump

- Underdrive pressure

- Low & reverse pressure

Repair procedures

Removal

1. Remove the battery and the battery trау. (Refer to "Charging system" in EE group.)

2. Remove the under cover (A).

Tightening torque: 19.6 ~ 24.5 N.m (2.0 ~ 2.5 kgf.m, 14.5 ~ 18.1 lb-ft)

3. Replace new gasket and the plug after draining the automatic transaxle fluid by removing the drain plug. (Refer to "Hydraulic system (Fluid)" in this group)

4. Remove the valve body cover (A) and eyebolt (B).

Tightening torque:

(A) 13.8 ~ 14.7 N.m (1.3 ~ 1.5 kgf.m, 9.4 ~ 10.8 lb-ft)

(B) 34.3 ~ 44.1 N.m (3.5 ~ 4.5 kgf.m, 25.3 ~ 32.6 lb-ft)

CAUTION

Always replace the gasket of the eyebolt use new one whenever loosening eyebolt.

5. Remove the plate and the detent spring (A) after removing the bolt.

Tightening torque: 24.5 ~ 35.3 N.m (2.5 ~ 3.6 kgf.m, 18.1 ~ 26.0 lb-ft)

6. Remove the bolt (3ea) after disconnecting the solenoid valve (B) connector and the oil temperature sensor connector (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

7. Remove the valve body assembly (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

Installation

1. Installation is the reverse of removal.

CAUTION

After replacement or reinstallation procedure of the valve body assembly, must perform procedures below.

NOTE

- Continue to apply liquid gasket at application points at the valve body cover with Ø2.5mm (0.0984in.) thickness.

Liquid gasket Part name : Threebond 1281B or LOCTITE FMD-546

- Adding automatic transaxle fluid. (Refer to "Hydraulic system (Fluid)" in this group)

- Perform TCM learning after replacing the valve body to prevent slow transaxle response, jerky acceleration and jerky startup. (Refer to "Automatic transaxle control system (Repair procedures)" in this group)

READ NEXT:

Description and Operation, Components and Components Location | Flow Diagram

Description and Operation, Components and Components Location | Flow Diagram

Description and Operation

Description

The 6-spd automatic transaxle consists of an overdrive clutch (OD/C), a one-way clutch (OWC), a lower and reverse brake (LR/B), an underdrive brake (UD/B

SEE MORE:

Windshield Glass

Windshield Glass

Components and Components Location

Components

Windshield side

molding

Windshield glass

Repair procedures

Replacement

Removal

CAUTION

Put on gloves to protect your hands.

Use seat covers to avoid damaging any surfaces

1. Remove the following items

Front pilla

Key positions

Key positions

Your vehicle is equipped with four different

ignition positions.

Illuminated ignition switch

Whenever a front door is opened, the

ignition switch will illuminate for your

convenience, provided the ignition

switch is not in the ON position.

The light will go off immediately when

the ignit

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles