Kia Sportage: Transaxle Oil Temperature Sensor

Description and Operation

Description

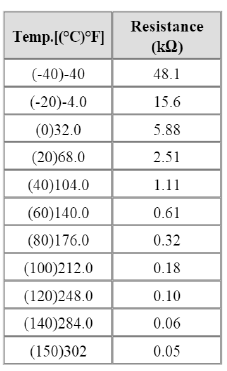

Transaxle oil temperature sensor monitors the automatic transaxle fluid's temperature and conveys the readings to TCM. It is an NTC (Negative Thermal Coefficient) sensor whose resistance has an inversely proportional relationship with the temperature level. Data produced by this sensor is used to identify damper clutch activation and deactivation zones within the low temperature and high temperature range and to compensate hydraulic pressure levels during gear changes.

Specifications

Specifications

Type: Negative Thermal Coefficient Type

Schematic Diagrams

Circuit Diagram

Repair procedures

Inspection

1. Turn ignition switch OFF.

2. Disconnect the oil temperature sensor connector.

3. Measure resistance between sensor signal terminal and sensor ground terminal.

4. Check that the resistance is within the specification

Removal

1. Remove the battery and the battery tray. (Refer to "Charging system" in EE group.)

2. Remove the under cover (A).

Tightening torque: 19.6 ~ 24.5 N.m (2.0 ~ 2.5 kgf.m, 14.5 ~ 18.1 lb-ft)

3. Replace new gasket and the ping after draining the automatic transaxle fluid by removing the drain ping. (Refer to "Hydraulic system (Fluid)" in this group)

4. Remove the valve body cover (A) and eyebolt (B).

Tightening torque:

(A) 13.8 ~ 14.7 N.m (1.3 ~ 1.5 kgf.m, 9.4 ~ 10.8 lb-ft)

(B) 34.3 ~ 44.1 N.m (3.5 ~ 4.5 kgf.m, 25.3 ~ 32.6 lb-ft

CAUTION

Always replace the gasket of the eyebolt use new one whenever loosening eyebolt.

5. Disconnect the oil temperature sensor connector (A).

6. Remove the oil temperature sensor (A) after removing a bolt.

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

Installation

1. Installation is the reverse of removal.

NOTE

After replacement or reinstallation procedure of the valve body assembly, must perform procedures below.

- Continue to apply liquid gasket at application points at the valve body cover with Ø2.5mm (0.0984in.) thickness.

Liquid gasket Part name : Threebond 1281B or LOCTITE FMD-546

- Adding automatic transaxle fluid. (Refer to "Hydraulic system (Fluid)" in this group)

READ NEXT:

Input Speed Sensor

Input Speed Sensor

Description and Operation

Description

Input speed sensor is a vital unit that measures the rate of rotation of the

input shaft inside the transaxle and delivers

the readings to the TCM. The

Output Speed Sensor

Output Speed Sensor

Description and Operation

Description

The output speed sensor is a vital unit that measures the rate of rotation of

the transaxle's turbine shaft and output

shaft, and delivers the read

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Description and Operation

Description

Torque converter control solenoid valve (T/CON_VFS) is attached to the valve body. This variable force solenoid valve directly controls the hydraulic pre

SEE MORE:

Components and Components Location | Rear Glass Defogger Printed Heater

Components and Components Location | Rear Glass Defogger Printed Heater

Component Location

Rear glass defogger relay

Rear glass defogger switch

Rear glass defogger

Rear Glass Defogger Printed Heater

Repair procedures

Inspection

CAUTION

Wrap tin foil around the end of the voltmeter test lead to prevent damaging the heater line. Ap

AUTO HOLD

AUTO HOLD

The Auto Hold is designed to maintain

the vehicle in a standstill even though

the brake pedal is not pressed after the

driver brings the vehicle to a complete

stop by pressing the brake pedal.

Applying Auto Hold function

Press the brake pedal and start the

vehicle.

Press the Auto Hold b

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles