Kia Sportage: Steering Gear box

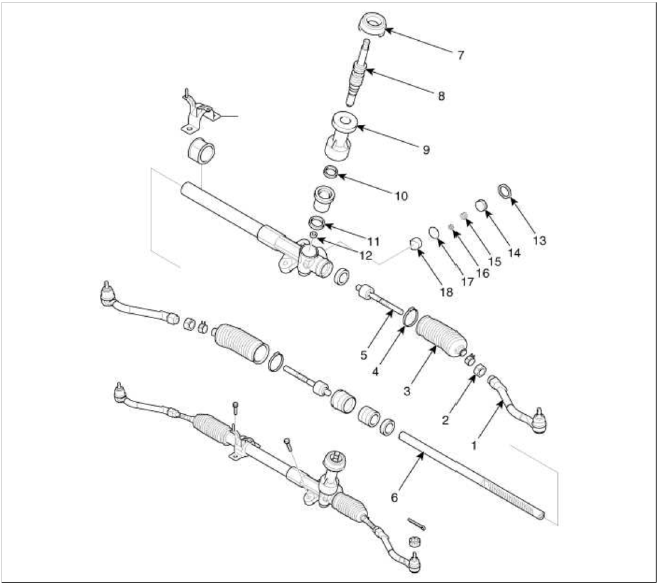

Components and Components Location

Components

- Tie rod end

- Locknut

- Bellows

- Bellows band

- Tie rod

- Rack bar

- Dust packing

- Pinion assembly

- Dust cap

- Oil seal

- Ball bearing

- Needle bearing

- Lock nut

- Yoke plug

- Yoke spring

- O-ring

- Spring

- Support yoke assembly

Repair procedures

Replacement

1. Remove the front wheel & tire.

Tightening torque: 88.3 ~ 107.9N.m (9.0 ~ 11.0kgf.m, 65.1 ~ 79.6lb-ft)

CAUTION

Be careful not to damage to the hub bolts when removing the front wheel & tire (A).

2. Disconnect the stabilizer link (B) with the front stint assembly (A) after loosening the nut.

Tightening torque: 98.1 ~ 117.7N.m (10.0 ~ 12.0kgf.m, 72.3 ~ 86.8lb-ft)

3. Remove the split pin and castle nut and then disconnect the tie-rod end (A) from the front knuckle.

Tightening torque: 23.5 ~ 33.3N.m(2.4 ~ 3.4kgf.m, 17.4 ~ 24.6lb-ft)

4. Loosen the bolt & nut and then remove the lower arm (A).

Tightening torque: 98.1 ~ 117.7N.m (10.0 ~ 12.0kgf.m, 72.3 ~ 86.8lb-ft)

5. Remove the dust cover.

6. Loosen the bolt (A) and then disconnect the universal joint assembly from the pinion of the steering gear box.

Tightening torque: 32.4 ~ 37.3N.m (3.3 ~ 3.8kgf.m, 23.9 ~ 27.5lb-ft)

CAUTION

- Keep the neutral-range to prevent the damage of the clock spring inner cable when you handle the steering wheel.

- Do not use the bolt again.

7. Remove the under cover (A).

8. Loosen the bolt (A) & nut (B) and then remove the roll rod stopper.

Tightening torque: 107.9 ~ 127.5N.m (11.0 ~ 13.0kgf.m, 79.6 ~ 94.0lb-ft)

9. Disconnect the muffler rubber hanger (A).

10. Loosen the bolts & nuts and then remove the sub frame.

Tightening torque: 176.5 ~ 196.1N.m (18.0 ~ 20.0kgf.m, 130.2 ~ 144.7lb-ft)

11. Loosen the bolt and then remove the stabilizer (A).

Tightening torque: 44.1 ~ 53.9N.m (4.5 ~ 5.5kgf.m, 32.5 ~ 39.8lb-ft)

12. Loosen the bolt & nut and then remove the protector (A).

13. Loosen the bolt and then remove the steering gear box (A).

Tightening torque: 58.8 ~ 78.5N.m (6.0 ~ 8.0kgf.m, 43.4 ~ 57.9lb-ft)

14. Installation is the reverse of the removal.

Disassembly

1. Remove the dust packing & cap (A) from the pinion housing.

2. Loosen the lock nut and then remove the tie rod end (B) and lock nut (A) from the tie rod.

3. Remove the bellows clip (A) and band (B) and then pull the bellows (C) away from the end of the tie rod.

4. Remove the tie rod (B) from the rack bar (A) by unscrewing the tie rod inner ball joint.

5. Remove the plug (A) from the pinion housing.

6. Remove the oil seal (B) from the plug (A).

7. Remove the yoke plug (A) and spring (B) and then pull out the support yoke (C).

8. Remove the O-ring (B) from the support yoke assembly (A).

9. Pull the pinion assembly (A) out of the pinion housing.

10. Pull the rack bar (A) out of the rack housing.

11. Reassembly is the reverse of the disassembly.

Inspection

1. Rack bar

- Check the rack gear for damage.

- Check the rack bar for bend and deformation.

2. Pinion assembly

- Check the pinion gear for damage

- Check the oil seal for damage

3. Check the inside of rack housing for damage.

4. Check the bellows for being torn.

READ NEXT:

General Information

General Information

Specifications

Specifications

Front Suspension

Rear Suspension

Wheel & Tire

Wheel Alignment

Tightening torque

Front Suspension

Rear Suspension

Special Service Tools

&nb

SEE MORE:

Components and ComponentsLocation | Disassembly - Repair procedures

Components and ComponentsLocation | Disassembly - Repair procedures

Components

Piston ring

Snap ring

Piston

Connecting rod

Connecting rod upper bearing

Piston pin

Connecting rod lower bearing

Connecting rod bearing cap

Ladder frame

Oil filter bracket

Crankshaft rear oil seal

Crankshaft upper

Waterproof and rustproof

Waterproof and rustproof

Sealing

To waterproof and rustproof the vehicle, apply sealer on assembled area of

the body panel and on any areas in

contact with the body, such as doors (inner/outer), hood (inner/outer), and tail

gate (inner/outer).

Body (Floor)

View

Section

Door

View

Section

Hood

Se

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles