Kia Sportage: Radiator

Components and Components Location

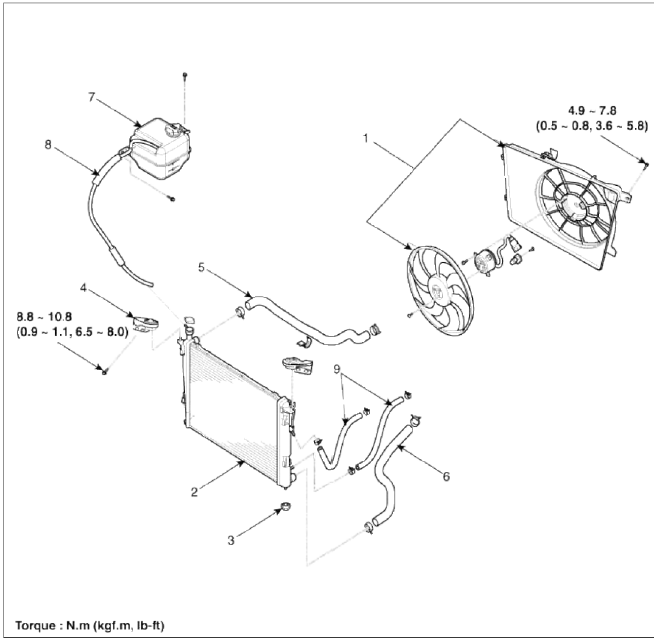

Components

- Cooling fan assembly

- Radiator assembly

- Mounting insulator

- Radiator mounting bracket

- Radiator upper hose

- Radiator lower hose

- Reservoir tank

- Over flow hose

- ATF cooler hoses

Repair procedures

Inspection

Radiator Cap Testing

1. Remove the radiator cap, wet its seal with engine coolant, and then install it on a pressure tester.

2. Apply a pressure of 93.16 ~ 122.58kPa (0.95 ~ 1.25kgf/cm2, 13.51 ~ 17.78psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

Radiator Leakage Test

1. Wait until engine is cool, then carefully remove the radiator cap and fill the radiator with engine coolant, then install it on the pressure tester (A).

2. Apply a pressure tester to the radiator and apply a pressure of 93.16 ~ 122.58kPa (0.95 ~ 1.25kgf/cm2, 13.51 ~ 17.78psi).

3. Inspect for engine coolant leaks and a drop in pressure.

4. Remove the tester and reinstall the radiator cap.

NOTE

Check for engine oil in the coolant and/or coolant in the engine oil.

Removal and Installation

1. Disconnect the battery terminals. (Refer to Engine and transaxle assembly in this group)

2. Remove the air cleaner assembly and intercooler inlet/outlet hose & pipes. (Refer to Engine and transaxle assembly in this group)

3. Remove the battery and battery tray. (Refer to Engine and transaxle assembly in this group)

4. Remove the radiator grill upper guard (A). (Refer to BD group)

5. Remove the radiator upper cover (A).

6. Remove the horn bracket (A). (Refer to BE group)

7. Remove the radiator front air guard (B).

8. Seperate the condenser (C) from the radiator.

9. Disconnect the over flow hose (A) from the radiator.

10. Remove the radiator mounting bracket assemblies (A).

Tightening torque: 8.8 ~ 10.8 N.m (0.9 ~ 1.1 kgf.m 6.5 ~ 8.0 lb-ft)

11. Disconnect the fan motor connector (A).

12. Remove the cooling fan assembly (A).

Tightening torque: 4.9 ~ 7.8 N.m (0.5 ~ 0.8 kgf.m, 3.6 ~ 5.8 lb-ft)

13. Remove the under cover. (Refer to Engine and transaxle assembly in this group)

14. Loosen the drain plug, and drain the engine coolant. Remove the radiator cap to drain with speed.

15. Disconnect the radiator upper hose (A) and lower hose (B).

16. Disconnect the ATF cooler hoses. (Refer to AT group)

17. Remove the radiator assembly (A).

18. Installation is the reverse order of removal.

19. Fill the radiator with coolant and check for leaks.

NOTE

- Bleed air from the cooling system.

- Start engine and let it run until it warms up. (Until the radiator fan operates 3 or 4 times.)

- Turn off engine. Check the coolant level and add coolant if needed. This will allow trapped air to be removed from the cooling system.

- Put the radiator cap on tightly, then run engine again and check for leaks.

READ NEXT:

Water pump

Water pump

Components and Components Location

Components

Water pump pulley

Water pump sub assembly

Water pump gasket

Water pump cover

Water pump cover gasket

O-ring

Water inlet pipe

Wa

Thermostat

Thermostat

Repair procedures

Removal and Installation

NOTE

Disassembly of the thermostat would have an adverse effect, causing a

lowering of cooling efficiency. Do not

remove the thermostat, even if the en

SEE MORE:

Front Wiper Motor

Front Wiper Motor

Components and

Components Location

Component Location

Cap

Nut

Wiper arm & blade

Clip

Cowl top cover

Bolt

Wiper motor & linkage assembly

Wiper motor connector

Repair procedures

Removal

1. Remove the windshield wiper arm and blade after

Heating and air conditioning manually

Heating and air conditioning manually

The heating and cooling system can be controlled manually by pressing buttons

other than the AUTO button.

In this case, the system works sequentially according to the order of buttons

selected.

Start the vehicle.

Set the mode to the desired position.

For improving the effectiveness

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles