Kia Sportage: Ð/С Pressure Transducer | Evaporator Temperature Sensor

Components and Components Location

Component Location

Description and Operation

Description

Ð/С pressure transducer convert the pressure value of high pressure line into voltage value after it is measured. By voltage value, the engine ECU controls cooling fan by operating it high speed or low speed. Engine ECU stops the operation of compressor when the temperature of refrigerant line is too high or too low to optimize air conditioning system.

Repair procedures

Inspection

1. Measure the pressure of high pressure line by measuring voltage output between NO.1 and NO.2 terminals.

2. Inspect the voltage value whether it is sufficient to be regular value or not.

Voltage = 0.00878835 * Pressure + 0.37081095 [PSIA]

3. If the measured voltage value is not specification, replace the Ð/С pressure transducer.

Replacement

1. Disconnect the negative (-) battery terminal.

2. Recover the refrigerant with a recovery/charging station.

3. Disconnect the Ð/С pressure transducer connector (3P) (A).

Tightening torque: 10~12 N.m (1.0~1.2 kgf.m, 7.4~8.8 lb-ft)

CAUTION

Take care that liquid & suction pipe are not bent.

4. Installation is the reverse order of removal.

Evaporator Temperature Sensor

Description and Operation

Description

The evaporator temperature sensor will detect the evaporator core temperature and interrupt compressor relay power in order to prevent evaporator freezing by excessive cooling.

Repair procedures

Inspection

1. Ignition "OFF".

2. Disconnect evaporator temperature sensor.

3. Using the multi-tester, Measure resistance between terminal "1" and "2" of evaporator temperature sensor.

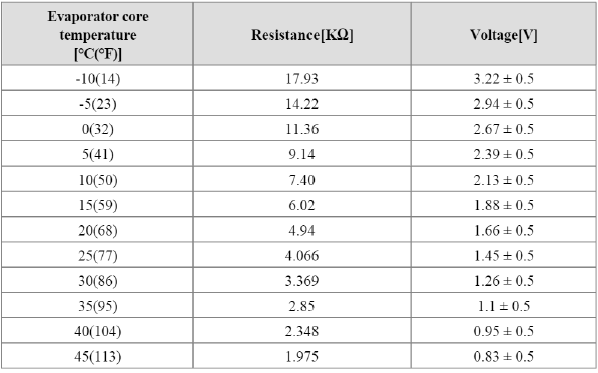

Specification

Replacement

1. Remove the console extension cover (A).

2. Remove the evaporator temperature sensor (A), by pulling it after rotating 90º in a clockwise direction.

3. Installation is the reverse order of removal.

READ NEXT:

Photo Sensor | Ambient Sensor

Photo Sensor | Ambient Sensor

Description and Operation

Description

1. The photo sensor is located at the right of defrost nozzle.

2. The photo sensor contains a photovoltaic (sensitive to sunlight) diode. The solar radiation

SEE MORE:

Power Mosfet | Blower Resistor | Climate Control Air Filter

Power Mosfet | Blower Resistor | Climate Control Air Filter

Repair procedures

Inspection

1. Ignition "ON".

2. Manually operate the control switch and measure the voltage of blower motor.

З. Select the control switch to raise voltage until high speed.

Specification

*AUTO COOLING : Auto speed (4.5V~B+) *AUTO HEATING : Auto speed (4

Blind-Spot Collision-Avoidance Assist settings

Blind-Spot Collision-Avoidance Assist settings

Setting features

Blind-Spot Safety

Driver Assistance

Blind-Spot Safety

Active Assist

Warning Only

Off

With the engine on, select or deselect

Settings?Driver Assistance ? Blind-

Spot Safety the User Settings menu or

select or deselect Settings? Vehicle ?

Driver Assistance

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles