Kia Sportage: PDM Relay Box

Components and Components Location

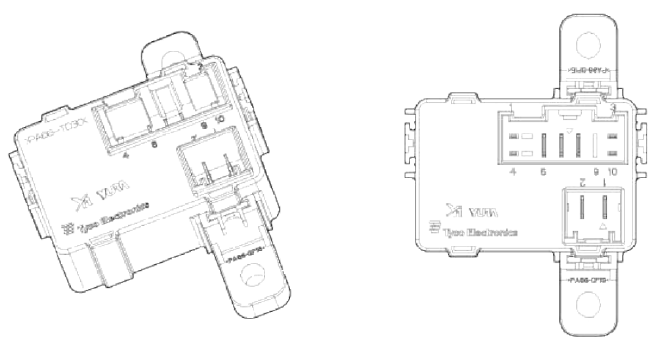

Components

Connector A (10 pins)

Connector A (10 pins)

- Smart key unit

- -

- Ground

- Smart key unit

- -

- ACC

- Battery power (IGN-1)

- IGN-1

- -

- Smart key unit

Connector Ð’ (2 pins)

Connector Ð’ (2 pins)

- IGN-2

- Battery power (IGN-2)

Description and Operation

Description

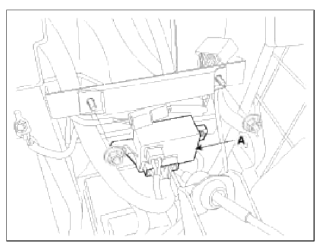

The PDM relay (A) is united with IG1, IG2 and ACC relays and installed in the lower center fascia panel.

Repair procedures

Removal

PDM Relay

1. Disconnect the negative (-) battery terminal.

2. Remove the floor console assembly.

(Refer to BD group - "Console")

3. Remove the PDM relay box (A) after loosening the bolts (2EA) and disconnecting the connector.

Installation

1. Install the PDM relay box.

2. Install the floor console assembly.

3. Connect the battery (-) cable.

Inspection

IG2 Relay

Check for continuity between the terminals.

1. There should be continuity between the No.1 and No.2 terminals in the Ð’ connector when power and ground are connected to the No.3 and No.4 terminals in the A connector.

2. There should be no continuity between the No.1 in the Ð’ and No.2 terminals in the Ð’ terminals when power is disconnected.

IG1 Relay

Check for continuity between the terminals.

1. There should be continuity between the No.7 and No.8 terminals in the A connector when power and ground are connected to the No.3 and No.10 terminals in the A connector.

2. There should be no continuity between the No.7 in the A and No.8 terminals in the A terminals when power is disconnected.

ACC Relays

Check for continuity between the terminals.

1. There should be continuity between the No.7 and No.6 terminals in the A connector when power and ground are connected to the No.1 and No.3 terminals in the A connector.

2. There should be no continuity between the No.7 in the A and No.6 terminals in the A terminals when power is disconnected.

READ NEXT:

Components and Components Location | Instrument Cluster

Components and Components Location | Instrument Cluster

Component Location

Cluster assembly

Seat belt switch

Vehicle speed sensor

Engine coolant temperature sender

Oil pressure switch

Brake fluid level warning swit

SEE MORE:

Components and Components Location | Description and Operation

Components and Components Location | Description and Operation

Components

Hands free call switch

Mic

Front left speaker

Front right speaker

Audio head unit (hands free control)

There is no hands free jack. This system supports Ð’luetooth (wireless system).

Description and Operation

Function

Bluetooth Audio

Lane Keeping Assist malfunction and limitations

Lane Keeping Assist malfunction and limitations

Lane Keeping Assist malfunction

Check Lane Safety system

When Lane Keeping Assist is not working

properly, the warning message will

appear and the yellow ( ) indicator

light will appear on the cluster. If this

occurs, have the function inspected by

an authorized Kia dealer.

Limitati

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles