Kia Sportage: Oil hydraulic Motor (Actuator)

Description and Operation

Description

The 4WD ECM controls the Pump Motor Pump (Actuator) to generating an oil pressure. The pressure engages a multiple disk clutch to transfer torque to the rear wheels. The torque to the rear wheels varies according to the pressure on the clutch.

Schematic Diagrams

Circuit Diagram

Repair procedures

Inspection

NOTE

If you have trouble code related to the oil hydraulic motor (actuator) (P1825, P1826, P1827, P1828), check oil hydraulic motor (actuator) according to the inspection process.

Oil Hydraulic Motor (Actuator) Inspection Procedure

Removal

1. Remove the coupling assembly. (Refer to "coupling assembly" in 4WD group).

2. Keep going perpendicular state after remove the coupling assembly.

NOTE

- Keep going perpendicular state during remove (install) the hydraulic motor (actuators).

3. Remove the hydraulic motor (actuators) after loosening bolts with hex wench.

CAUTION

- Remove the hydraulic motor (actuators) after dropping residual oil as much as possible inside the coupling. (abut 5-10 sec)

Installation

1. Before installation, wipe the surface with a clean cloth.

2. Check the О-rings of the new hydraulic motor (actuators).

CAUTION

- You have to prevent any dust from entering inside hydraulic motors (actuators) and housing.

3. Tighten the bolts after install the hydraulic motor (actuators).

CAUTION

- When installing, motor connector has to toward in the direction of outside of the Coupling.

Tightening torque: 8.8 ~ 10.8 N.m (0.9 ~ 1.1 kgf.m, 6.5 ~ 8.0 lb-ft)

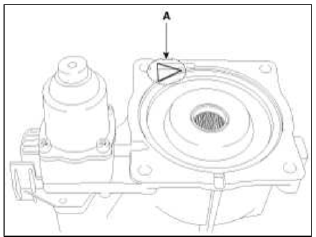

NOTE

- When installing, oil can be reflux by the pressure in aft breather hole. (Oil reflux weight: about 5 ~ 10 ml)

- Change direction in the direction of the arrow and lay on the floor

as shown in the illustration.

The reflux oil will flow to the bottom.

- You have to prevent additional backflow in according to order as shown in the illustration.

4. Wipe the flowed oil to around the surface with a clean cloth.

5. Measure the weight of the coupling.

Coupling assembly weight: 8.18 ~ 8.23kg (Current oil capacity 490ml)

CAUTION

- If the weight of the coupling assembly is less than 8.18kg, must be replace the coupling assembly because of suspect excessive reflux.

READ NEXT:

Pressure Sensor

Pressure Sensor

Description and Operation

Description

The 4WD ECU makes a Motor Pump (Actuator) turn round for generating an oil

pressure. And then it presses a multiple

disk clutch and transfers the gener

General Information

General Information

Specifications

Specifications

VFS: Variable Force Solenoid

Sensors

Input Speed Sensor

Type: Hall effect sensor

Specifications

Output Speed Sensor

Type: Hall effe

SEE MORE:

Rear Body, Under Body

Rear Body, Under Body

Rear Body

Body Repair

* These dimensions indicated in this figure are actual-measurement

dimensions.

Under Body

Body Repair

Projected Dimensions

* These dimensions indicated in this figure are actual-measurement

dimensions.

Actual-Measurement Dimensions

* These

If the engine overheats

If the engine overheats

If your temperature gauge indicates

overheating, you experience a loss of

power, or hear a loud pinging or knocking,

the engine will probably be too hot.

If this happens, you should:

Pull off the road and stop as soon as it

is safe to do so.

Shift the gear to P (Park) and set the

par

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles