Kia Sportage: Fuel Pressure Control Valve | Electric WGT Control Actuator

Description and Operation

Description

Fuel Pressure Regulator Valve is installed on the high pressure fuel pump and controls fuel flow flowing into the injectors in accordance with the ECM signal calculated based on various engine condition.

Specifications

Specification

Troubleshooting

Signal Waveform

Schematic Diagrams

Circuit Diagram

Repair procedures

Inspection

1. Turn the ignition switch OFF and disconnect the battery negative (-) cable.

2. Disconnect the fuel pressure regulator valve connector.

3. Measure resistance between the fuel pressure regulator valve terminals 1 and 2.

4. Check that the resistance is within the specification

Specification: Refer to "Specification"

Removal

Refer to "High Pressure Fuel Pump" in this group.

Installation

Refer to "High Pressure Fuel Pump" in this group.

Electric WGT Control Actuator

Description and Operation

Description

The Electric WGT Control Actuator is installed on the turbocharger.

It operates the vain in the Waste Gate Turbocharger (WGT) and regulates the compressed air amount by the ECM's PWM signal. This actuator consists of a DC motor which actuates the vane, a 2-step gear which increases torque of the DC motor, a position sensor which detects status of the vane, an electric control unit which drives the DC motor.

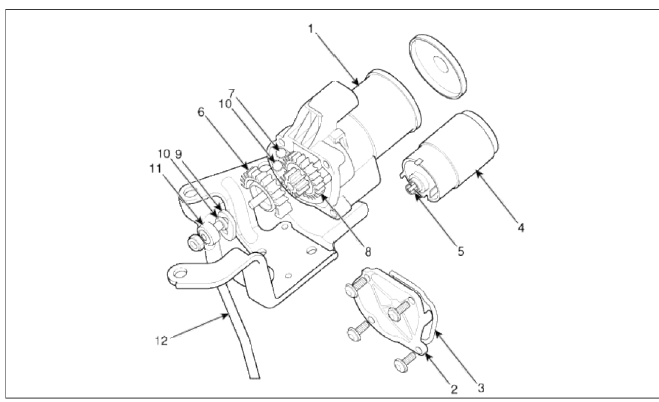

Components and Components Location

Components

- Housing

- Cover

- Sealing Cover

- Motor

- Pinion

- Shaft Gear

- PCB Assembly

- Middle Gear

- Lever

- Lever Pin

- Rod - End

- Rod

Specifications

Specification

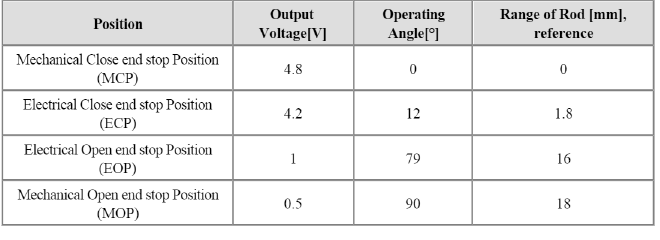

[EWGA Position Sensor]

![[EWGA DC Motor]](images/books/1921/22/index%206.png)

[EWGA DC Motor]

Troubleshooting

Signal Waveform

Schematic Diagrams

Circuit Diagram

Repair procedures

Inspection

[Motor]

1. Turn ignition switch OFF.

2. Disconnect the EWGA connector.

3. Check that the EWGA is stuck by foreign material.

4. Measure resistance between motor (+) and (-) control terminals of the motor.

5. Check that the resistance is within the specification.

Specification: Refer to "Specification" section.

[Position Sensor]

1. Turn ignition switch ON.

2. Connect the GDS to the data link connector (DLC).

3. Check the output voltage at each position of the EWGA position sensor on current data item within the specification.

Specification: Refer to "Specification" section.

Removal

1. Turn the ignition switch OFF and disconnect the battery negative (-) cable.

2. Disconnect the EWGA connector (A).

3. Remove the shaft link assembly (B) after removing the C-ring (A).

4. Remove the EWGA after removing the bolts (A).

CAUTION

When carrying the turbo charger, do not hold the rod of the turbo charge to prevent bending the rod.

Installation

1. Installation is the reverse order of removal.

Adjustment

1. Turn ignition switch OFF.

2. Connect a GDS Data Link Connector (DLC).

3. Turn ignition switch ON.

4. Select "Current data".

5. Loosen the rod end lock nut (A) remove the C-ring (B).

6. Adjust the rod end part (C) by rotating it at the direction of clockwise or counter clockwise to satisfy the specification.

- If output voltage > 4.2 : Clockwise (D)

- If output voltage < 4.2 : Counter Clockwise (E

Specification : 4.2 +- 0.1V

7. Check output voltage on current data in GDS after installing the rod end part (C) without the clip.

If output voltage satisfy the specification, fix the rod end part with clip.

READ NEXT:

RCV Control Solenoid Valve | Canister Close Valve (CCV)

RCV Control Solenoid Valve | Canister Close Valve (CCV)

Description and Operation

Description

RCV (Recirculation Valve) Control Solenoid Valve is installed on the intercooler inlet pipe and operates the RCV actuator which controls the by-pass pass

SEE MORE:

Camshaft

Camshaft

Repair procedures

Removal

Timing chain cover removal is not required for this procedure.

CAUTION

Use fender covers to avoid damaging painted surfaces.

To avoid damaging the cylinder head, wait until the engine coolant

temperature drops below normal

temperature before removing it.

Supplemental Restraint System (SRS) care

Supplemental Restraint System (SRS) care

The Supplemental Restraint System

(SRS) is virtually maintenance-free and

so there are no parts you can safely service

by yourself.

If the SRS air bag warning light does not

appear, or continuously remains on,

have your vehicle immediately inspected

by an authorized Kia dealer.

Any work

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles