Kia Sportage: Front Disc Brake

Components and Components Location

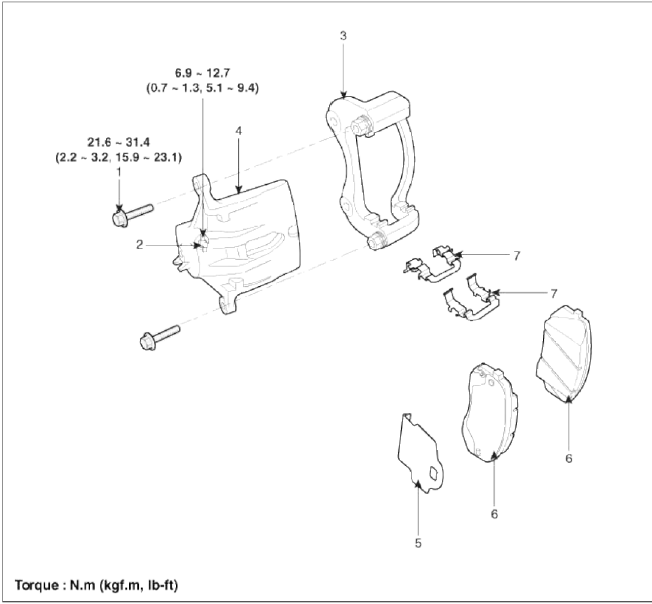

Components

- Guide rod bolt

- Bleed screw

- Caliper bracket

- Caliper body

- Inner pad shim

- Brake pad

- Pad retainer

Repair procedures

Removal

1. Remove the front wheel & tire.

Tightening torque: 88.3 ~ 107.9 N.m (9.0 ~ 11.0 kgf.m, 65.1 ~ 79.6 lb-ft)

2. Loosen the hose eyebolt (B) and caliper mounting bolts (C), then remove the front caliper assembly (A).

Tightening torque:

Brake hose to caliper (B): 24.5 ~ 29.4 N.m (2.5 ~ 3.0 kgf.m, 18.1 ~ 21.7 lb-ft)

Caliper assembly to knuckle (C): 78.5 ~ 98.1 N.m (8.0 ~ 10.0 kgf.m, 57.9 ~ 72.3 lb-ft)

3. Remove the front brake disc by loosening the screws (A).

Replacement

Front brake pads

1. Remove the brake hose mounting bracket bolt (A).

2. Loosen the guide rod bolt (B) and pivot the caliper (A) up out of the way.

Tightening torque: 21.6 ~ 31.4 N.m (2.2 ~ 3.2 kgf.m, 15.9 ~ 23.1 lb-ft)

3. Replace pad shim (D), pad retainers (C) and brake pads (B) in the caliper bracket (A).

Inspection

Front brake disc thickness check

1. Check the brake pads for wear and fade.

2. Check the brake disc for damage and cracks.

3. Remove all rust and contamination from the surface, and measure the disc thickness at 8 points, at least, of same distance (5mm) from the brake disc outer circle.

Brake disc thickness

[2WD]

- Standard : 26 mm (1.02 in)

- Service Limit: 24.4 mm (0.96 in)

[4WD]

- Standard : 28 mm (1.10 in)

- Service Limit: 26.4 mm (1.04 in)

Deviation: Less than 0.005 mm (0.0002 in)

4. If wear exceeds the limit, replace the discs arid pad assembly left and right of the vehicle.

Front Brake Pad Check

1. Check the pad wear. Measure the pad thickness and replace it, if it is less than the specified value.

Pad thickness

Standard value: 11 mm (0.43 in)

Service limit: 2.0 mm (0.0787 in)

2. Check that grease is applied, to sliding contact points and the pad and backing metal for damage.

Front brake disc runout check

1. Place a dial gauge about 5mm (0.2 in.) from the outer circumference of the brake disc, and measure the runout of the disc.

Brake disc runout

Limit: 0.025 mm (0.00098 in.) or less (new one)

2. If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again.

3. If the runout does not exceed the limit specification, install the brake disc after turning it 180º and then check the runout of the brake disc again.

4. If the runout cannot be collected by changing the position of the brake disc, replace the brake disc.

Installation

1. Installation is the reverse of removal.

2. Use a SST (09581-11000) when installing the brake caliper assembly.

3. After installation, bleed the brake system. (Refer to Brake system bleeding)

READ NEXT:

Rear Disc Brake

Rear Disc Brake

Components and Components Location

Components

Guide rod bolt

Bleed screw

Caliper bracket

Caliper body

Inner pad shim

Brake pad

Pad retainer

Repair procedures

Removal

1. R

Components and ComponentsLocation | Removal - Repair procedures

Components and ComponentsLocation | Removal - Repair procedures

Components (1)

[Hand Type] / [Foot Type]

Parking brake pedal assembly

Front parking brake cable (Foot type only)

Equalizer assembly

Rear parking brake cable

Parkin

SEE MORE:

Preparation for assembly - Replacing body panel

Preparation for assembly - Replacing body panel

Preparation for assembly

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark. Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any bent or uneven areas with a hammer to

improve the assembly process.

3. Cutting a rough area for

Hazardous driving conditions

Hazardous driving conditions

If driving conditions deteriorate due to

poor weather or road conditions, you

should pay even more attention than

usual to your driving.

Hazardous driving conditions

When hazardous driving conditions are

encountered such as water, snow, ice,

mud, sand, or similar hazards, follow

these sugges

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles