Kia Sportage: Engine Control Module (ECM)

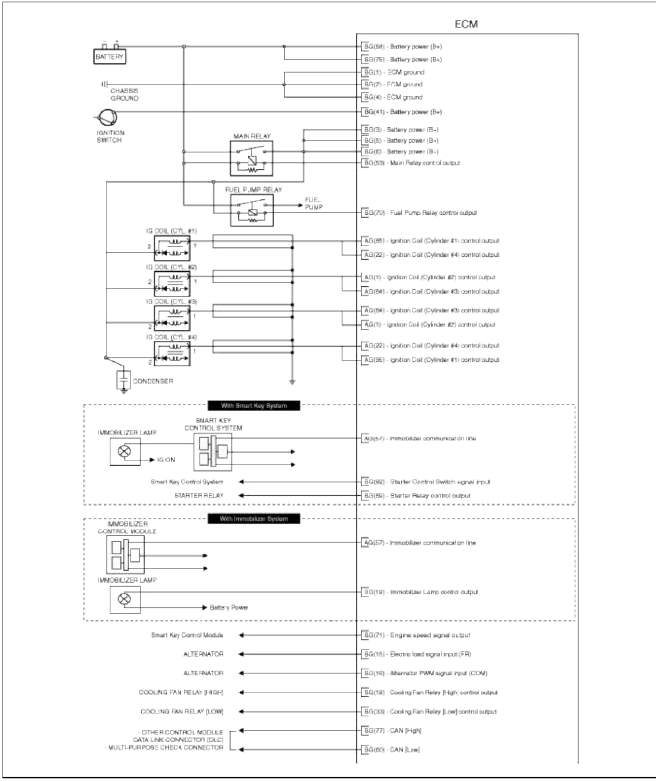

Schematic Diagrams

ECM Terminal And Input/Output signal

ECM Terminal Function

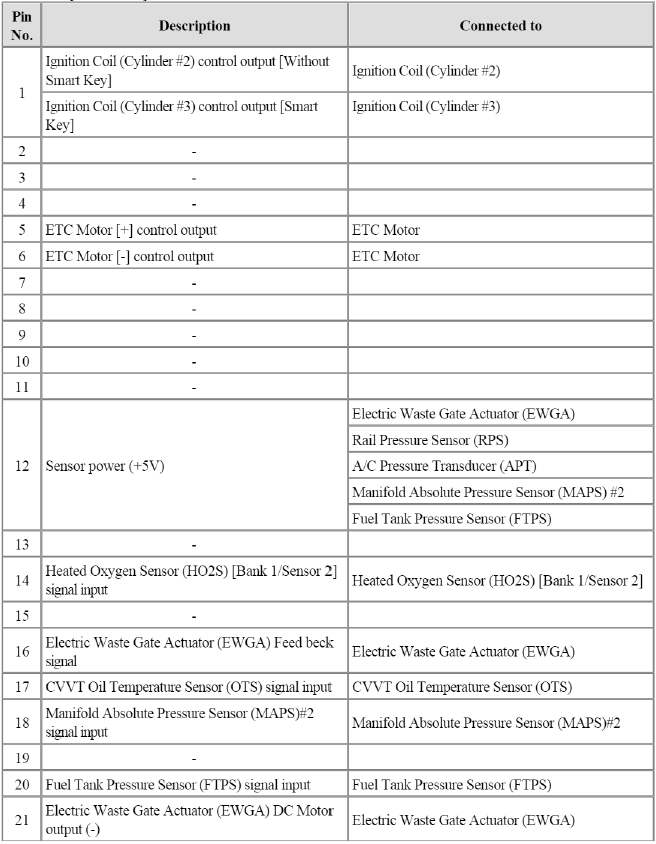

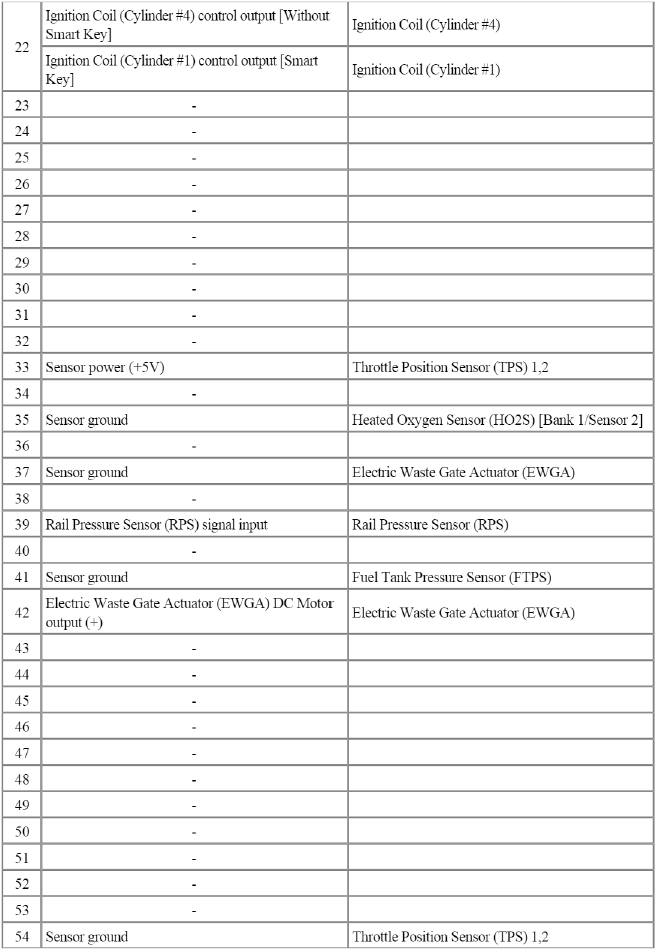

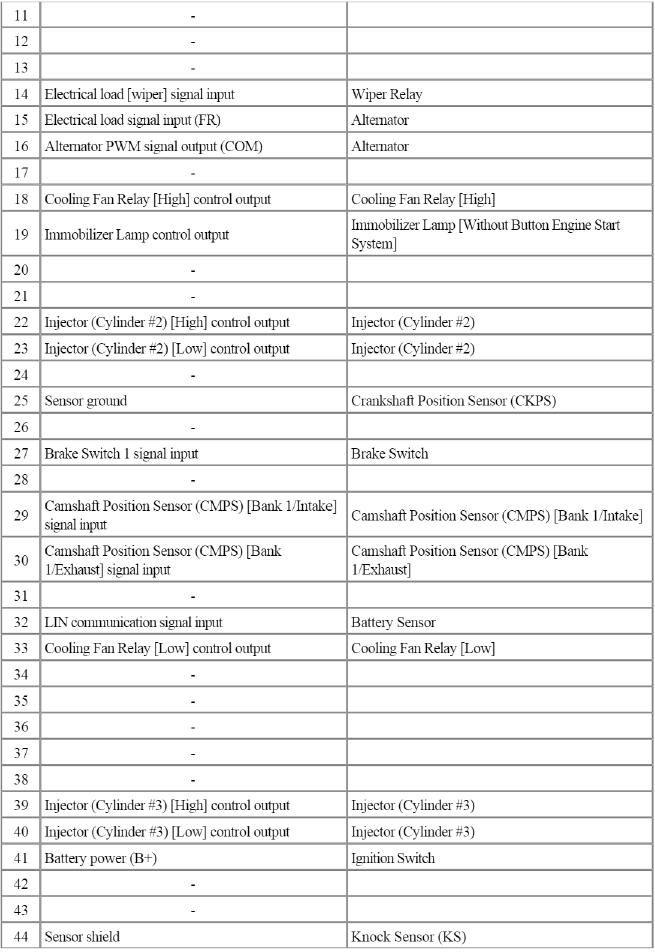

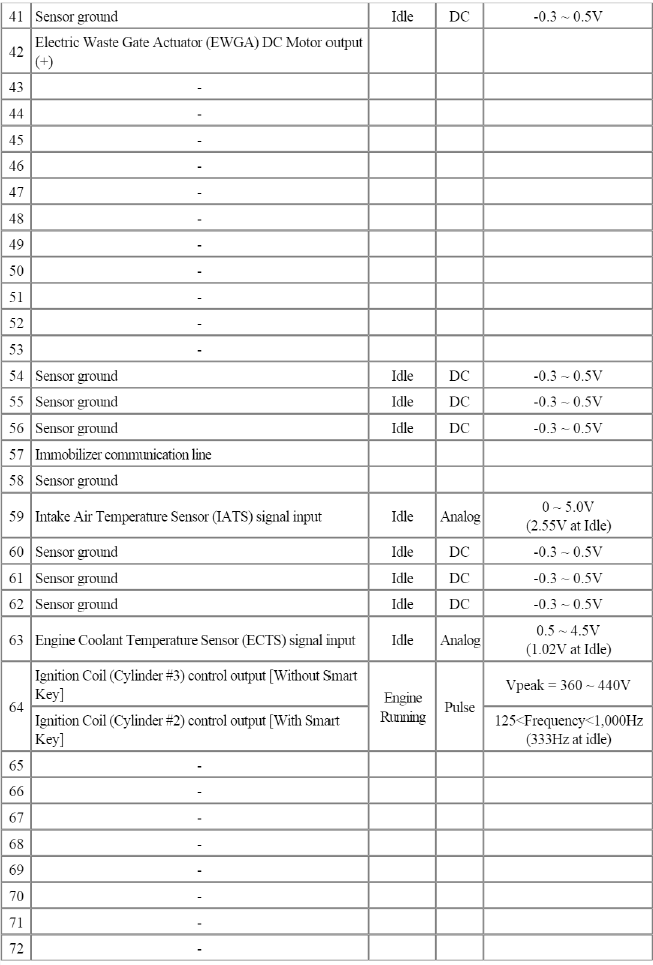

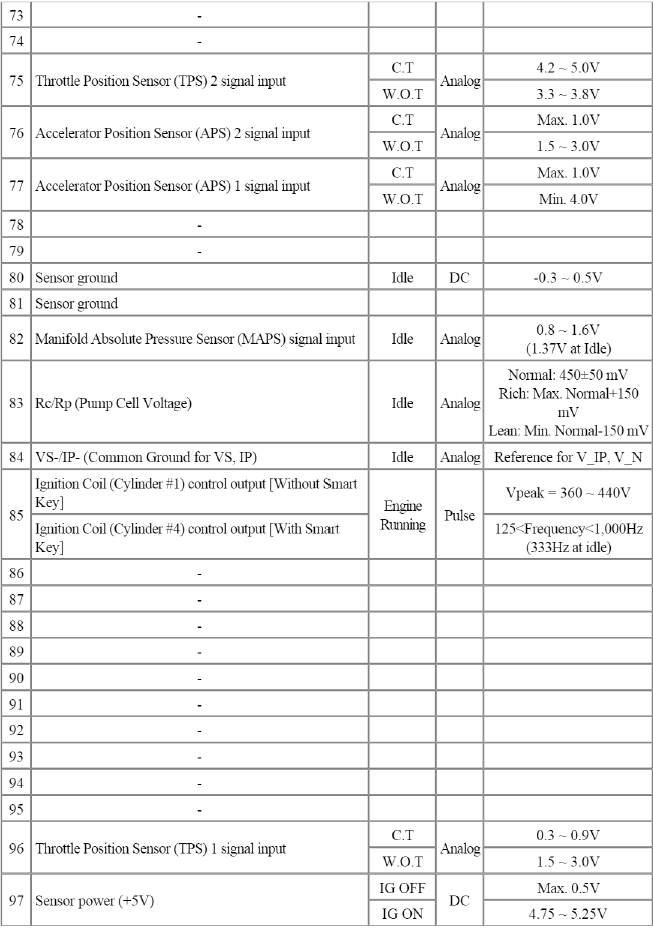

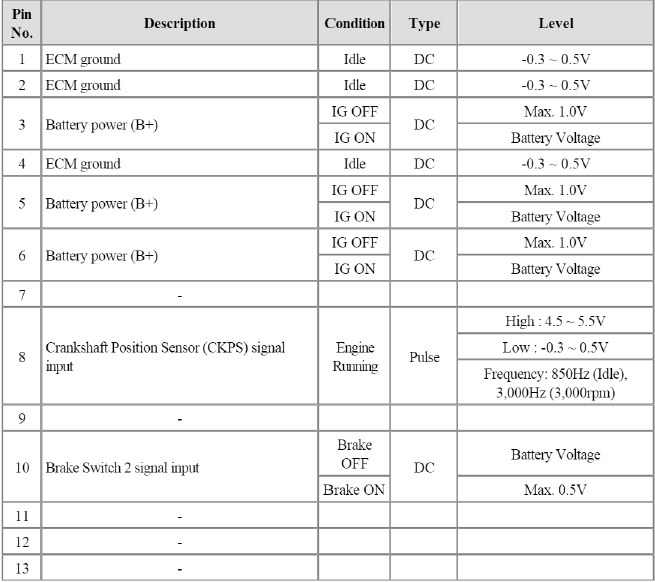

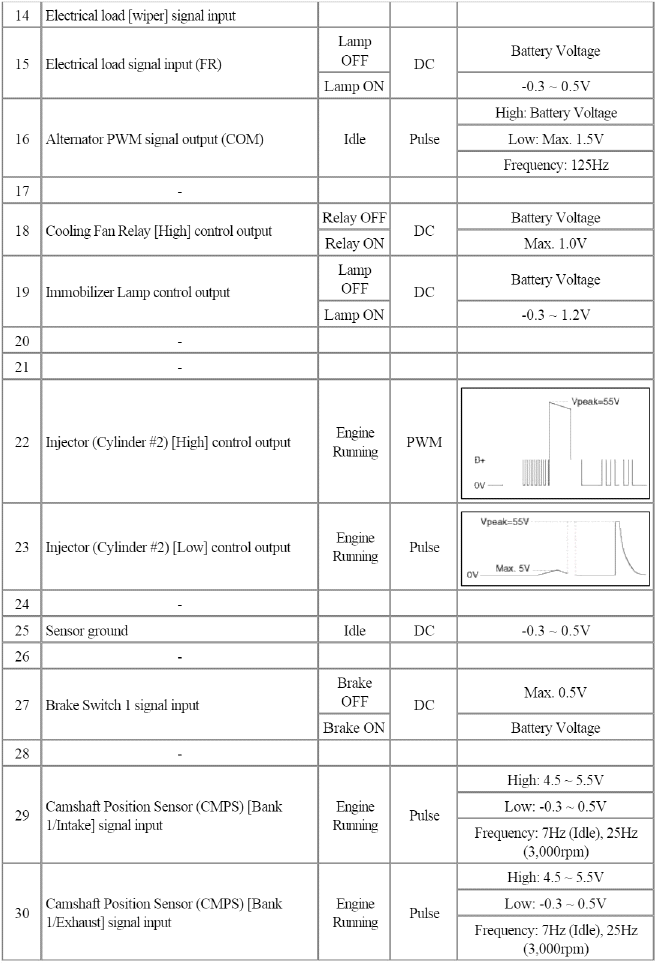

Connector [CHTG-AG]

![Connector [CHTG-BG]](images/books/1921/21/index%2075.png)

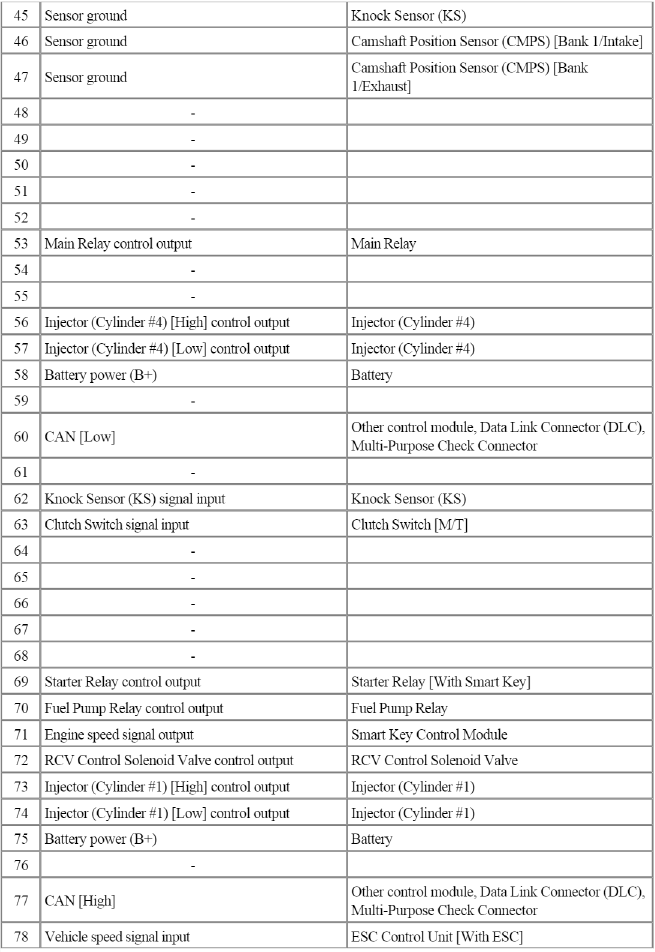

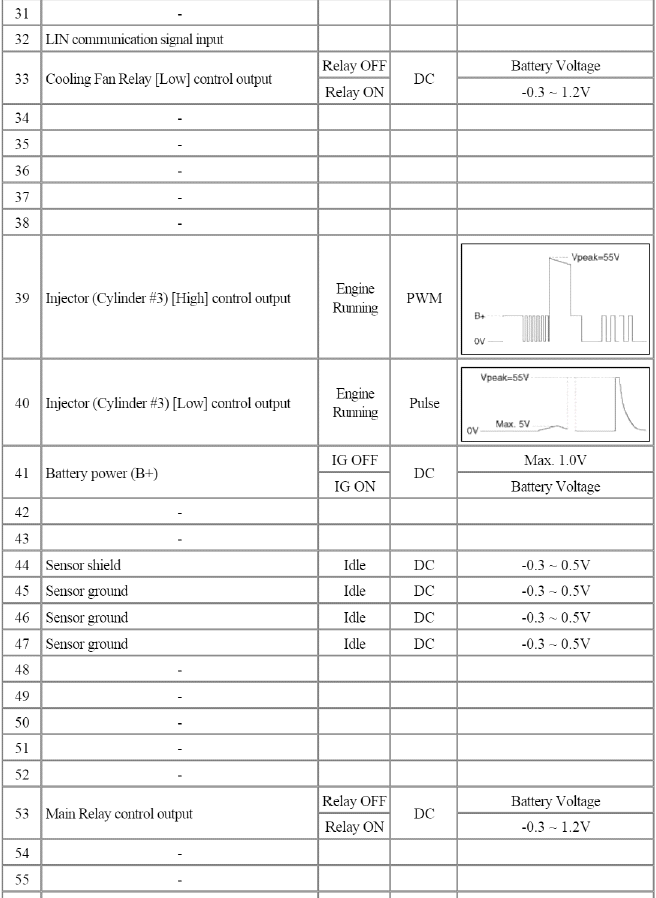

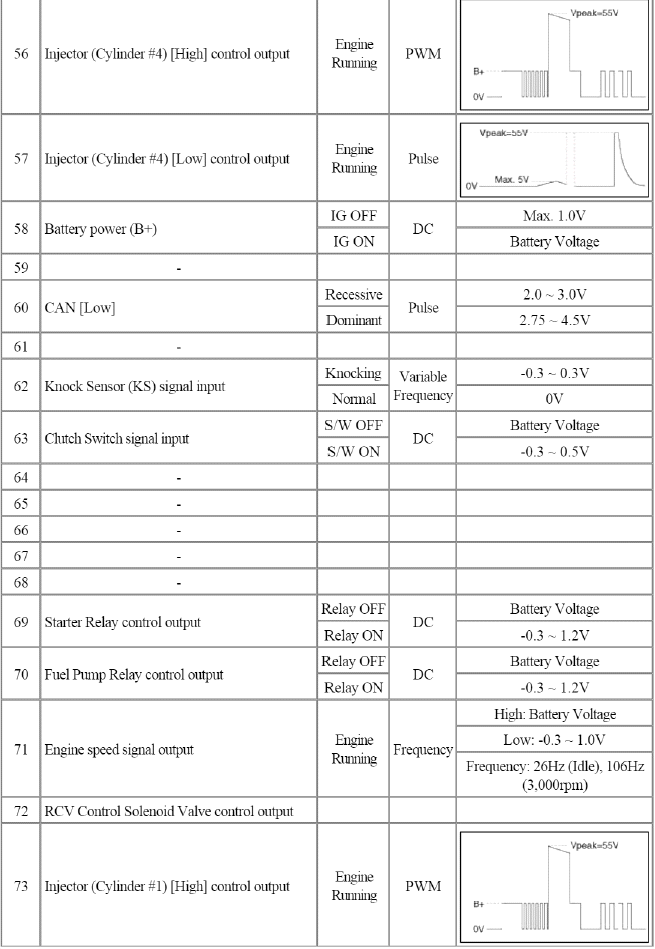

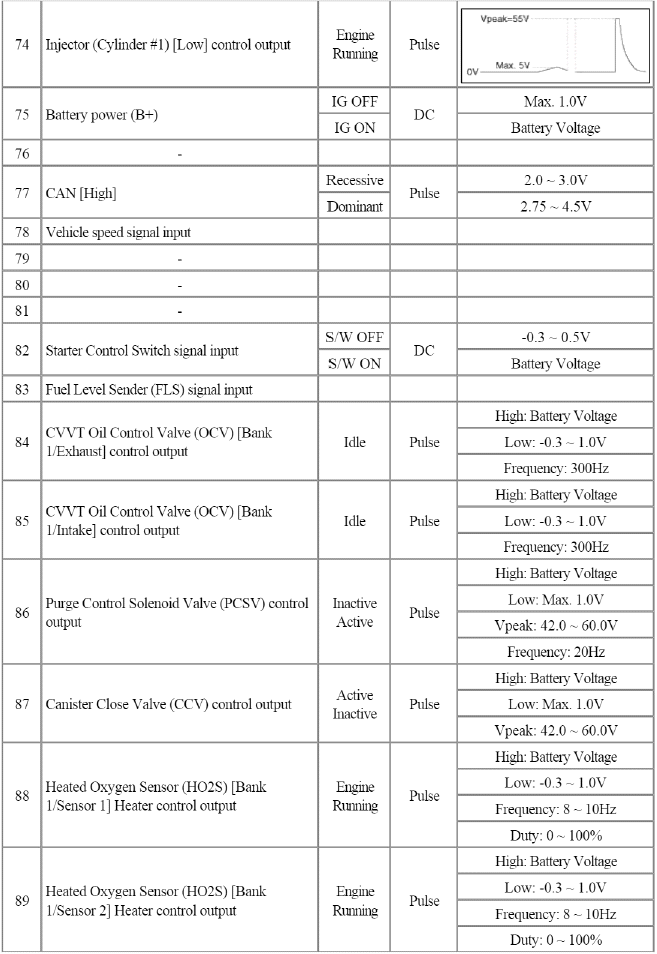

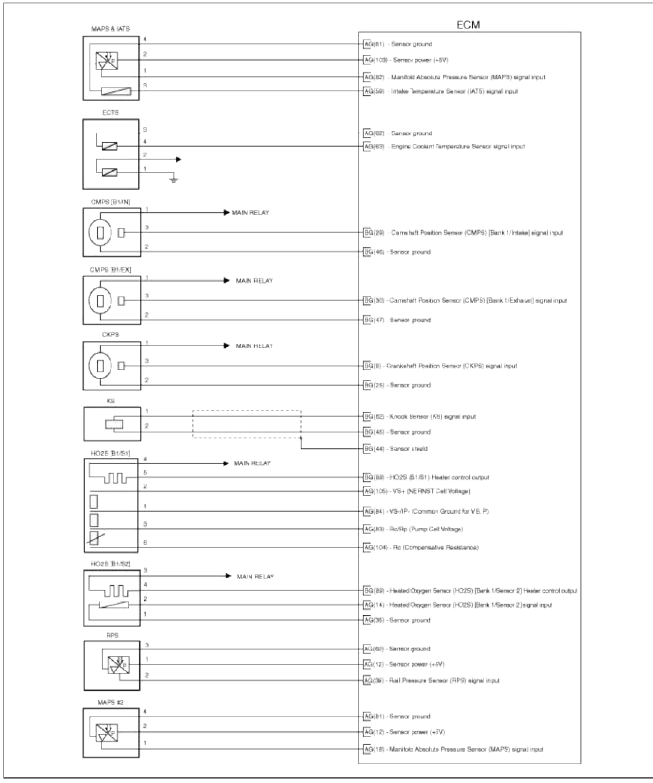

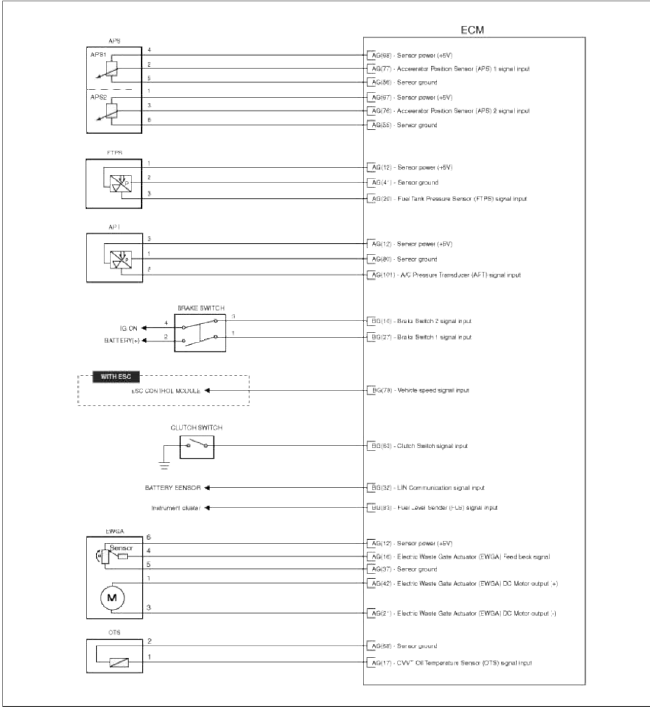

Connector [CHTG-BG]

ECM Terminal Input/Output signal

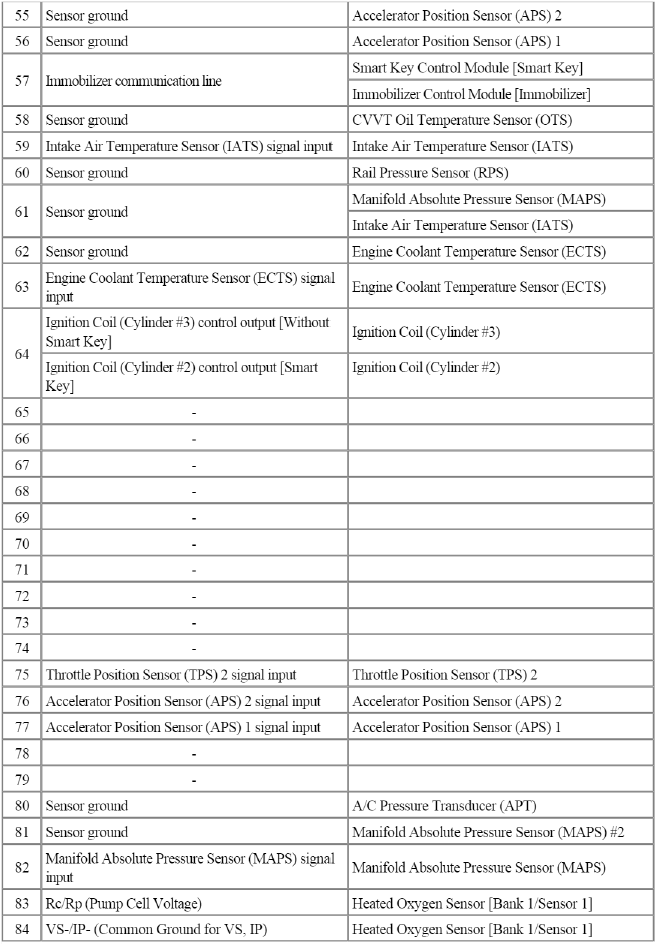

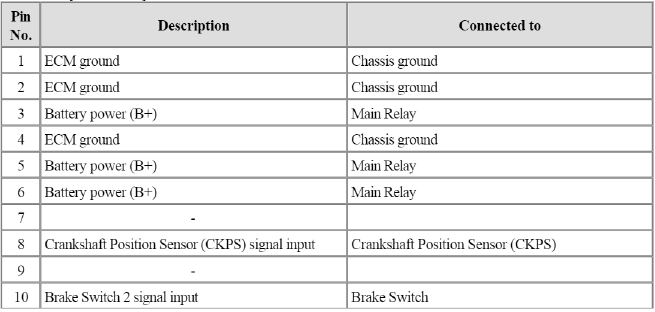

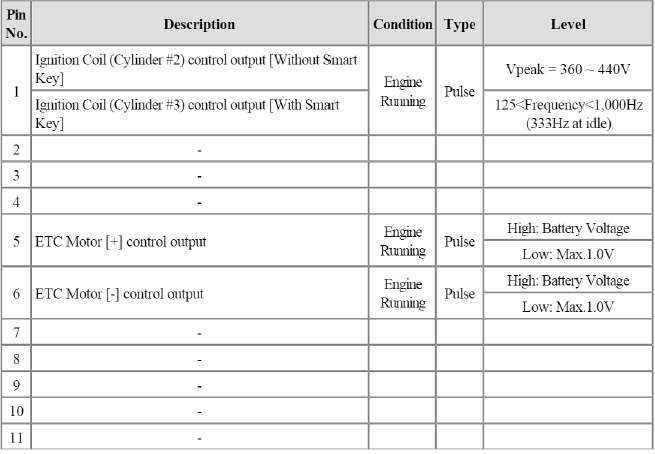

Connector [CHTG-AG]

![Connector [CHTG-BG]](images/books/1921/21/index%2084.png)

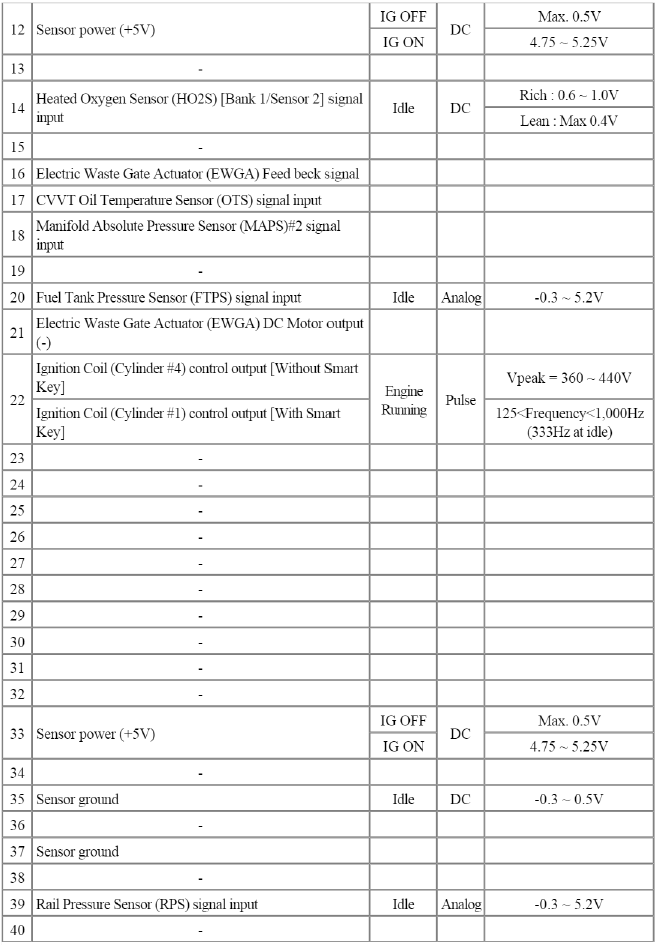

Connector [CHTG-BG]

Circuit Diagram

Repair procedures

Removal

CAUTION

When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below.

[In the case of installing used ECM]

- Perform "ECM Neutral mode" procedure with GDS. (Refer to "Immobilizer" in BE group)

- After finishing "ECM Neutral mode", perform "Key teaching" procedure with GDS. (Refer to "Immobilizer" in BE group)

[In the case of installing new ECM]

Perform "Key teaching" procedure with GDS. (Refer to "Immobilizer" in BE group)

CAUTION

When replacing the ECM, the vehicle equipped with the smart key system (Button start) must be performed procedure as below.

[In the case of installing used ECM]

- Perform "ECM Neutral mode" procedure with GDS. (Refer to "Smart key" in BE group)

- After finishing "ECM Neutral mode", insert the key (or press the start button) and turn it to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

[In the case of installing new ECM]

Insert the key (or press the start button) and turn it to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

1. Turn ignition switch OFF and disconnect the negative (-) battery cable.

2. Disconnect the ECM Connector (A).

3. Remove the battery (Refer to "Intake And Exhaust System" in EM group).

4. Remove the mounting bolts (A) and nut (B), and then remove the ECM assembly (C).

5. Remove the installation nuts (A), and then remove the ECM (B) from the bracket.

Installation

CAUTION

When replacing the ECM, the vehicle equipped with the immobilizer must be performed procedure as below.

[In the case of installing used ECM]

- Perform "ECM Neutral mode" procedure with GDS. (Refer to "Immobilizer" in BE group)

- After finishing "ECM Neutral mode", perform "Key teaching" procedure with GDS. (Refer to "Immobilizer" in BE group)

[In the case of installing new ECM]

Perform "Key teaching" procedure with GDS. (Refer to "Immobilizer" in BE group)

CAUTION

When replacing the ECM, the vehicle equipped with the smart key system (Button start) must be performed procedure as below.

[In the case of installing used ECM]

- Perform "ECM Neutral mode" procedure with GDS. (Refer to "Smart key" in BE group)

- After finishing "ECM Neutral mode", insert the key (or press the start button) and turn it to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

[In the case of installing new ECM]

Insert the key (or press the start button) and turn ft to the IGN ON and OFF position. Then the ECM learns the smart key information automatically.

1. Installation is reverse of removal.

ECM installation nut: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m,7.2 ~ 8.7 lb-ft)

ECM bracket installation bolt/nut: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m,7.2 ~ 8.7 lb-ft)

ECM Problem Inspection Procedure

1. TEST ECM GROUND CIRCUIT: Measure resistance between ECM and chassis ground using the backside of ECM harness connector as ECM side check point. If the problem is found, repair it.

Specification: Below 1Ω

2. TEST ECM CONNECTOR: Disconnect the ECM connector and visually check the ground terminals on ECM side and harness side for bent pins or poor contact pressure. If the problem is found, repair it.

3. If problem is not found in Step 1 and 2, the ECM could be faulty. If so, make sure there were no DTC's before swapping the ECM with a new one, and then check the vehicle again. If DTC's were found, examine this first before swapping ECM.

4. RE-TEST THE ORIGINAL ECM: Install the original ECM (may be broken) into a known-good vehicle and check the vehicle. If the problem occurs again, replace the original ECM with a new one. If problem does not occur, this is intermittent problem (Refer to "Intermittent Problem Inspection Procedure" in Basic Inspection Procedure).

READ NEXT:

ETC (Electronic Throttle Control) System

ETC (Electronic Throttle Control) System

Description and

Operation

Description

The Electronic Throttle Control (ETC) System consists of a throttle body with

an integrated control motor and

throttle position sensor (TPS). Instead

Manifold Absolute Pressure Sensor (MAPS)

Manifold Absolute Pressure Sensor (MAPS)

Description

and Operation

Description

Manifold Absolute Pressure Sensor (MAPS) is a speed-density type sensor and

is installed on the surge tank. It

senses absolute pressure of the surge t

Intake Air Temperature Sensor (IATS) | Engine Coolant Temperature Sensor (ECTS)

Intake Air Temperature Sensor (IATS) | Engine Coolant Temperature Sensor (ECTS)

Description and Operation

Description

Intake Air Temperature Sensor (IATS) is included inside Manifold Absolute Pressure Sensor and detects the intake air temperature.

To calculate precise a

SEE MORE:

Climate control air filter

Climate control air filter

Filter inspection

The climate control air filter should be

replaced according to the maintenance

schedule. If the vehicle is operated in

severely air-polluted cities or on dusty

rough roads for a long period, it should

be inspected more frequently and

replaced earlier. When you replace the

c

Declaration of conformity

Declaration of conformity

The radio frequency components

(Front Radar) complies:

For United States and United States territories

For Canada

The radio frequency components

(Rear Corner Radar) complies:

For United States and United States territories

For Canada

Radio frequency radiation exposure

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles