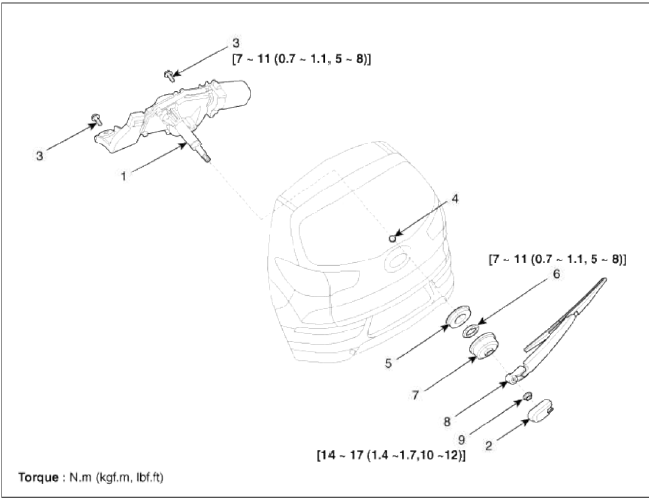

Kia Sportage: Components and Components Location | Rear Wiper Motor

Component Location

- Rear wiper motor assembly

- Head cap

- Rear wiper motor mounting bolt

- Rear wiper motor mounting hole

- Pad cap

- Hexagonal nut

- Cover

- Rear wiper arm & blade

- Rear wiper arm nut

Rear Wiper Motor

Repair procedures

Inspection

Rear Wiper Motor

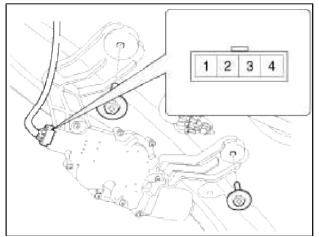

1. Remove the 4P connector from the rear wiper motor.

2. Connect battery positive (+) and negative (-) cables to terminals 2 and 1 respectively.

3. Check that the motor operates normally. Replace the motor if it operates abnormally.

- GND

- Switch

- Parking

- IGN(+)

Automatic Stop Operation Check

1. Operate the motor at low speed using the stalk control.

2. Stop the motor operation anywhere except at the off position by disconnecting terminal 2.

3. Connect terminals 2 and 3.

4. Connect the positive (+) lead from the battery to terminal 4 and the negative (-) lead to terminal 1.

5. Check that the motor stops running at the off position.

Removal

1. Detach the rear wiper head cap (A).

2. Remove the rear wiper arm & blade (A) after removing rear wiper arm nut (B).

3. Remove the rear wiper cover (A) and HEX nut (B).

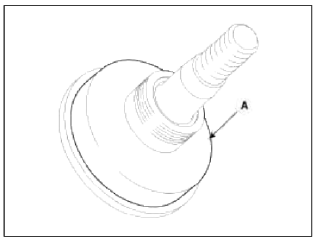

4. Remove the pad cap (A).

5. Open the tailgate then remove the tailgate trim.

(Refer to the BD group - "Tailgate")

6. Disconnect the rear wiper motor connector (A) then remove the rear wiper motor (B) after loosening bolts (2EA).

Installation

1. Install the rear wiper motor assembly

Tightening torque Nut: 7 ~ 11 N.m (0.7 ~ 1.1 kgf.m 5 ~ 8 lbf.ft)

NOTE

Do not reuse the rubber pad if it is damaged.

2. Install the tailgate trim.

(Refer to the BD group - "Tailgate")

3. Insert the pad cap and HEX nut.

Tightening torque: 7 ~ 11 N.m (0.7 ~ 1.1 kgf.m 5 ~ 8 lbf.ft)

4. Install the rear wiper arm and blade to align with black lowest rear defogger line (A).

5. Install the rear wiper arm and rear wiper nut.

Tightening torque Nut: 14 ~ 17 N.m (1.4 ~ 1.7 kgf.m 10 ~ 12 lbf.ft)

READ NEXT:

Rear Washer Switch | Rear Washer Motor

Rear Washer Switch | Rear Washer Motor

Repair procedures

Inspection

Check for continuity between the terminals while operating the wiper and washer switch. If it is not normal condition, replace wiper and washer switch.

Rear Wi

SEE MORE:

General Safety Information and

Caution

General Safety Information and

Caution

Instructions

When Handling Refrigerant

1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your

hand could result in localized frostbite.

When handling the refrigerant, be sure to wear gloves.

2. It is standard practice to wear goggles or glasses to protect your ey

Air bag collision sensors

Air bag collision sensors

* The actual shape and position of sensors may differ from the illustration.

Supplemental Restraint System (SRS) control module/rollover sensor

Front impact sensors

Side pressure sensors (front door)

Side impact sensors (B-pillar)

Side impact sensors (C-pillar)

WARNING

Air bag se

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2025) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles